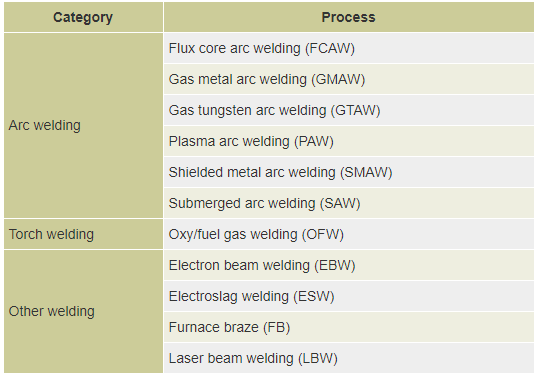

Common Hardfacing Processes

Fusion hardfacing is a process by which weld materials, with superior properties than the substrate, are applied to the substrate. Often, two layers total 3 - 6 mm (1/4 - 1/2 in) thick are applied to reduce the surface hardness dilution of the relatively low-cost steel substrates in the expansive cobalt-base alloys. Hardfacing processes are very useful for improving wear and corrosion resistance to selected areas of machinery, such as cutting edges of earth-moving machinery. Common hardfacing techniques include arc, torch, and other processes.

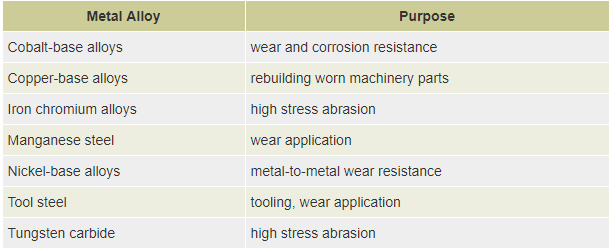

Common Materials Used in Hardfacings

Hardfacings are good for substrate materials that are suitable for welding, such as low-carbon steel. The most common hardfacing materials are nickel alloys and iron/chromium alloys used in wear resistance and high stress abrasion. Common materials for hardfacing are listed as follows: