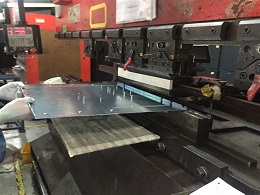

Fabrication is using sheet metal to build metal machines and structures. It can be a complex pro-cess involving many different professionals. Businesses that specialize in sheet metal fabrication are commonly referred to as fabrication shops, or fab shops for short. Sheet metal fabrication generally involves cutting and burning the sheet metal. Special tools, such as band saws, are used to cut the sheet metal. Band saws have special hardened blades and are capable of feeding the sheet metal to ensure even cutting. Chops saws are also used in sheet metal fabrication. Chop saws are similar to miter saws, but they have an abrasive disk specifically made for cutting sheet metal. Cutting torches are also used in sheet metal fabrication. Cutting torches are cable of cut-ting large sections of sheet metal with very little effort. Sheet metal fabrication also involves the use of hydraulic breaks. With hydraulic breaks, sheet metal fabrication is simplified, as they help create bends at predetermined angles. Rolling machines are also used in sheet metal fabrication to form steel into round sections. Another main focus of sheet metal fabrication is welding. After the sheet metal parts are formed, they are assembled and tack welded into place. Various weld-ing techniques can be used in sheet metal fabrication to avoid warping or other visual defects. These include using a stout fixture, welding in a staggered manner, covering the metal with sand during the cooling process, and special straightening processes. Straightening warped steel dur-ing sheet metal fabrication is accomplished with an Oxy-acetylene torch. With straightening, heat is applied to the metal in a slow, linear fashion. Using this method, a highly skilled welder can remove even significant warpage. To finish the sheet metal fabrication process, the metal is usual-ly sand blasted, then primed and painted. Then, the finishing touches are placed according to the customer's specifications, and the piece is inspected and shipped.

CMS: Built From Start To Finish

CMS provides custom metal fabrication for a variety of industrial groups. Based in Shanghai, China, we serve business throughout the nation and many other countries in the world. We have a metal manufacturer, providing high-quality steel, aluminum, brass, copper and stainless steel components through our use of cutting edge technology to enssure your order is produced to high accuracy and delivered on-time. Our metal fabrication shop is one of the best in China, and we have the best certified engineers, allowing us to provide our clients with the custom metal manufacturing meet or exceed their requirements.

Range of Services

We specialize in contract manufacturing, including welding, bending, stamping and deep drawing, metal fabrication services of varying complexities for industrial groups. Our services already applicated to agricultural, railroad, gas oil, energy, architectural, etc. For over 15 years, we have provided welding services, custom steel fabrication, stainless steel fabrication, brass and aluminum fabrication for companies all over the world.

We stock a wide variety of commonly-used steel, stainless steel, tubes, alminum to help ensure the quick turn-around of your project, and we have a crew of experienced metal fabricators who is the essence of enabling Ego to provide our customers a service of consistent quality while in a timely manner.

Our Services

| --Welding | --Bending |

--Stamping |

||

| 1. Robort Welder | 1. Manual Tuber And Pipe Benders | 1. Tooling Making | ||

| 2. MIG (GMAW) | 2. Hydraulic Tube And Pipe Benders | 2. Prototype Tooling | ||

| 3. TIG (GTAW) | 3. 3-Roll(Large Radius) Tube And Pipe Bender | 3. Stage Tooling | ||

| 4. Stick (SMAW) | 4. Dies for Tube And Pipe Benders |

4. Progressive Tooling | ||

| --Cutting | |

| 1. CNC Laser Cutting | 3. CNC Water-Jet Cutting |

| 2. CNC Plasma Cutting | 4. CNC Flame Cutting |

Secondary Services

1.CNC machining

2. Heat treatment to adjust metal physical and chemical properties

3. Surface treatment: Painting, Powder coating, Zinc plating, Nickel Plating, Anodizing, Galvanizing, polishing, etc...

4. Assembly

5. Customized; packaging, oil protection if needed.

Metal Fabrication Products

|

|

|

|

|

|

|

|

|

|

|

|