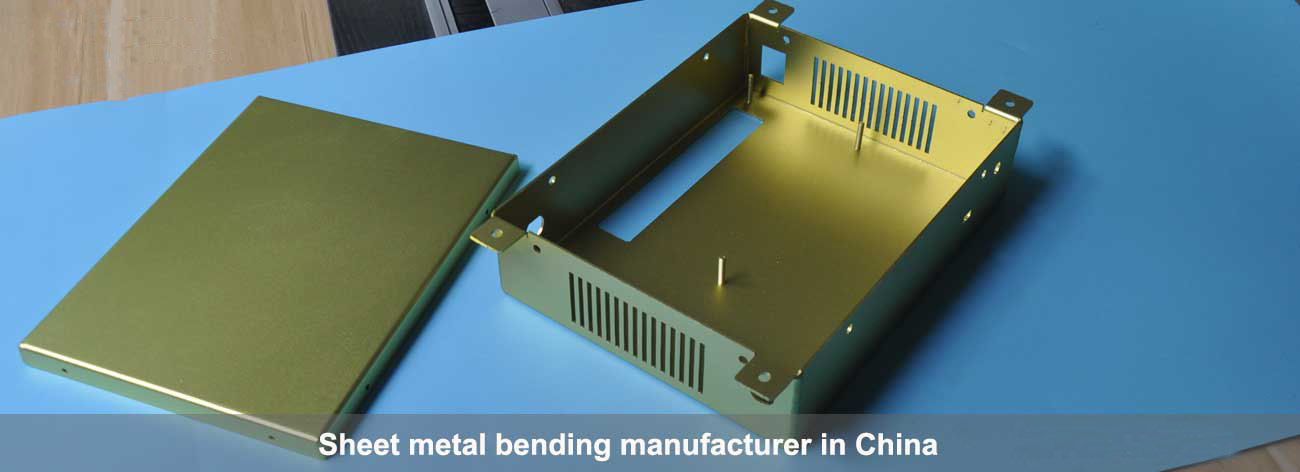

| Project Name | Custom bending aluminum heat sink box |

|---|---|

| Application | Electronic products,Industrial equipment enclosure, |

| Material | Aluminum, Stainless steel, steel |

| Machinery | Metal stamping China machine, CNC bending machine, TIG, and MIG welding machines |

| Processes | Sheet metal stamping process, bending, Welding. |

| Surface treatment & color | polish & plating,or painting, powder coating |

| Part Measurement | Customized |

| Tolerance required | Without marking DIN 2768-M; Special required at +/-0.1mm |

| Packaging | Carton +wood case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, ABS Material data sheet & Rohs SGS report |

|

CNC lasing cutting machine,Extend the parts in 2d drawing and input to CNC laser machine |

The sheet metal cut by CNC lasing machine or punching machine |

|

CNC punching machine can make hole or non-standard shape cut-out on a whole sheet. no tooling cost, high precision. high production efficiency. NO MOQ required. |

Bending the sheet metal according to design |

|

CNC bending machine |

Finished Aluminum bending heat sink |

|

TIG AC/DC welding or MIG welding for the corner Value-added service -welding, Miller welding machine works perfectly for the seal the corner

|

Butt Welding Some sheet metal stamping parts will be butt welded together according to clients design |

|

Thread Tapping Tapping the thread on sheet metal stamping parts up on parts design |

Custom finish upon your need, supply the parts surface treatment and finish including Anodizing,painting, plating and powder coating, More available finish that we do in-house please refer to page finishes |