Thermal Spraying

Common Thermal Spraying Processes

Popular in the 1990s, thermal spraying processes form a continuous coating by melting the consumable material (target) into droplets and impinging these droplets on the substrate. The mechanism of bonding to surface in thermal sprayings is the same as platings, both mechanical interlocking and atomic interaction, with the shear strength around 7 MPa (10 ksi). The thickness of the coatings may range from 25 µm to 2.5 mm (.001 - .1 in). In practice, the thermal sprayings are capable of competing with platings and paintings for atmospheric corrosion resistance in water tanks, TV towers, bridges, and other large steel structures.

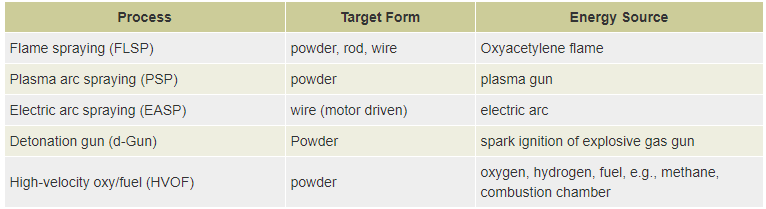

Some common thermal spraying processes, including Flame Spraying (FLSP), Plasma Arc Spraying (PSP), Electric Arc Spraying (EASP), Detonation Gun (d-Gun), and High-velocity Oxy/Fuel (HVOF), are briefly discussed as follows.

Flame Spraying (FLSP): FLSP was the first thermal spraying process. It use 2760 ºC (5000 ºF) oxyacetylene flame to melt the targets which may be powders, rods, or wires.

Plasma Arc Spraying (PSP): Similar to flame spraying, PSP however produces 16,650 ºC (30,000 ºF) heat for melting powders and yet the surface temperature of the substrate rarely exceeds 150 ºC (300 ºF). PSP is thus more suitable for spraying ceramics on metals and thermoset plastics for building up dimensions or wear resistance. The coatings are usually denser, contain less porosity, and have better adhesion than FLSP.

Electric Arc Spraying (EASP): EASP uses electric arc to melt the motor driven target wires. The melted droplets are then inject to the substrate surface by gas.

Detonation Gun (d-Gun): D-Gun melts target powders in a gun by spark ignition of explosive gas.

High-velocity Oxy/Fuel (HVOF): Executing in a combustion chamber, HVOF uses oxygen, hydrogen, and a fuel gas, e.g., methane, to melt the target powder. Resulting the better control in working environment, the HVOF serve the same function as plasma spraying and often have better quality control.

In summary: