Plastic blow molding uses the air pressure to blow the melted plastic blanks into the mold cavity to form a hollow featured part. The wall thickness for blow molding process is normally thin. Compare with injection molding process, the cost for blow molding is relatively low and better molding performance, so it can make the items in more complex shapes. The main products made by blow molding are including: Tool Box, Christmas Toys, Packing Bottles (Shampoo Bottle, Washing-up Liquid Bottle, Medical Bottle, Sport Drinking Bottle, Tissue Container, etc.), Sports Goods, Industrial Technology Accessories (such like Automotive Components, Automotive Radiator, Steam Tank and Engineering Water Tank), Decorative Lighting, and so on. Maxtech has imported high precision vacuum blow molding machines, so we can reach a maximum weight of 38kg. Common plastic materials include PE, PP, PVC, PC, PS, PA, PETG, EVA, PAN, PPE, PPO, ABS, POM, TRE and TRV.

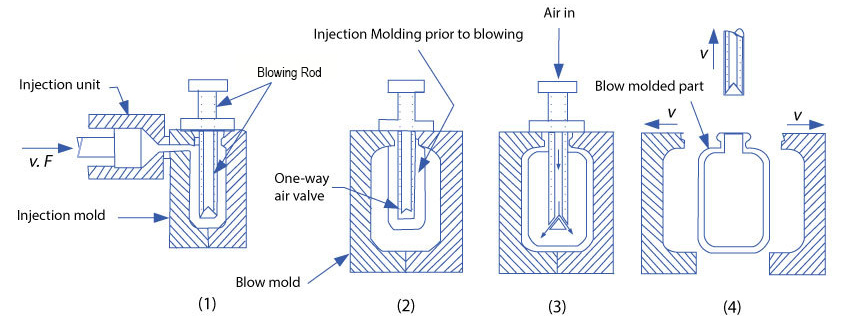

There are three steps of injection blow molded process, which are injection, blowing and finally ejection. The most common items made by injection blow molding process include water bottles, jars and plastic containers. Major features of injection blow molding process are precision dimensions, no flashes, and products are very nice-looking. This process has been widely used for making containers and bottles all over the world.

Bottles made by injection blow molding have thick walls and the wall-thickness is quite even. The parting lines are almost invisible and the bottle neck dimensions are very precision. Advantages of injection blow molding include low scrap rate, consistent weight, dimensions and wall-thickness, cost effective for high volume productions, and can make items in very small sizes.

Blow Molding vs Injection Molding:

The major differences between these two processes are the shape feature and the wall thickness.

Items made by blow molded process is hollow and items made by injection molding is solid.

In addition, wall thickness made by injection molding is fixed by the injection mold, it is not flexible. However, wall thickness made by blow molding can vary in places since it is determined by how much the material been stretched during the blowing process.

|

|

|

|

Mold Design & Manufacture |

Equipment & Production |

Secondary Operations |

Workshop

We satisfy our customers all over the world with our world class equipment and procedures. Our blow molding services include: extrusion blow molding, injection blow molding, and stretch blow molding. Each process matches different types products.

Extrusion blow molding is suitable for plastic bag shape type, injection blow molding is the best option for bottle shape with extra special structure, and stretch blow molding is for bottle shape without special construction.

|

|

|

|

|

|

Secondary Operations

1.Welding includes Ultrasonic Welding, Vibration Welding, Laser Welding;

2.Printing includes Hot Stamping/Decal, Silk-Screen Printing, Tempo Printing, Laser Engraving, Label Application;

3.Painting and texture;

4.Assembly with other fittings;

5.Customized packaging;

6.Provide certification like RoHS, Reach, CE...

Plastic Blowing Products

a.Extrusion Blow Molding(EBM)

|

|

|

|

|

|

b.Injection Blow Molding

|

|

|

|

|

|

|

|

|

c.Stretch Blow Molding

|

|

|

|

|

|