CNC TURNING SERVICE

The Basics Of CNC Turning

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

We use CNC turning not only to manufacture parts and prototypes but also to make mold tools, which can be used for our plastic injection molding or presure die casting services.

How CNC Turning Works

Turning involves holding the workpiece in a horizontally-mounted, adjustable spindle. As the workpiece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. On our Haas turning mills, an extra axis of movement allows us to work perpendicular to the lathe spindle for making square faces or boring holes. This opens up many new machining possibilities.

When all turning operations are completed, the part is cut from the stock for further post-processing. The CNC lathe is then ready to repeat the operation with little-to-no set-up time in between.

Types Of CNC Turning

The most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique in that stock material is fed through a guide bushing, allowing the tool to cut nearer to the point of support, which makes them particularly useful for long, slender turned parts and micromachining. Some Swiss-type lathes also come equipped with a second tool head that operates as a CNC mill, allowing them to perform multiple machining operations without having to move the workpiece to a different machine. This makes Swiss-type lathes extremely cost-effective for complex turned parts.

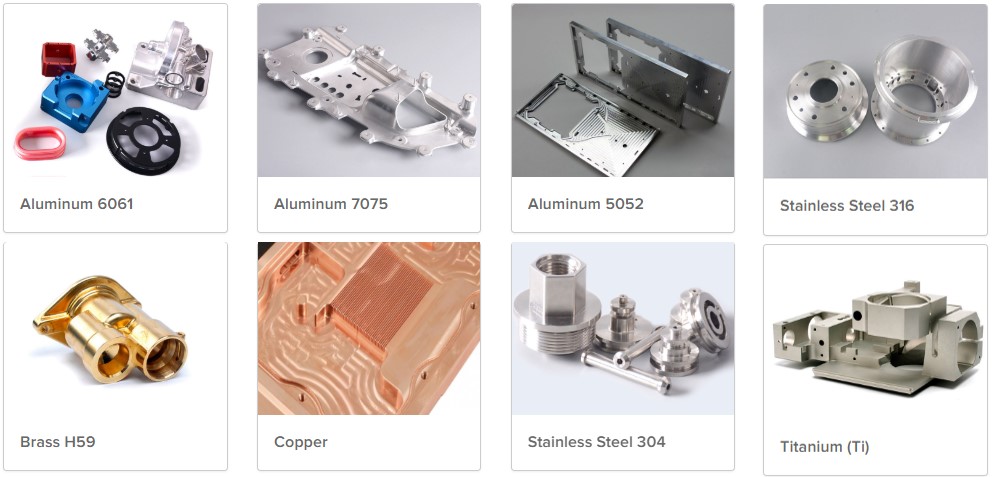

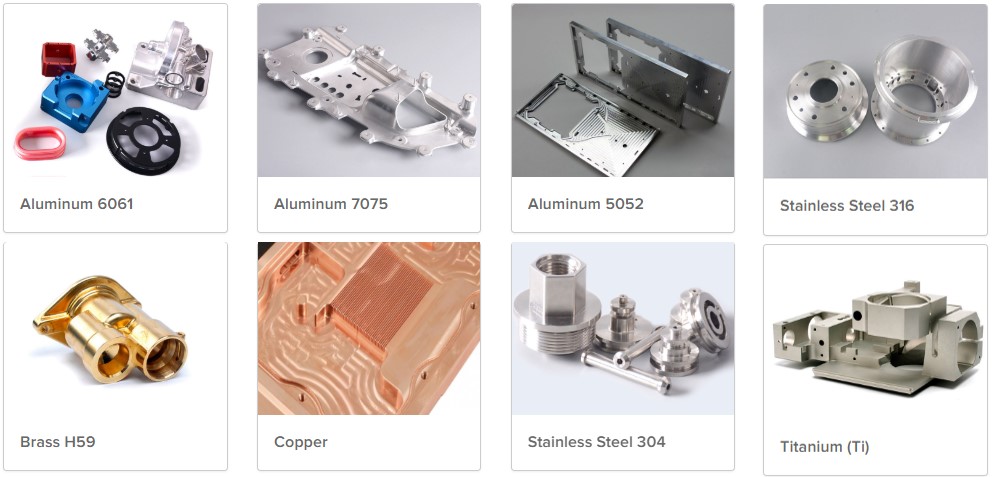

Available Materials

Available Finishes

|

|

|

|

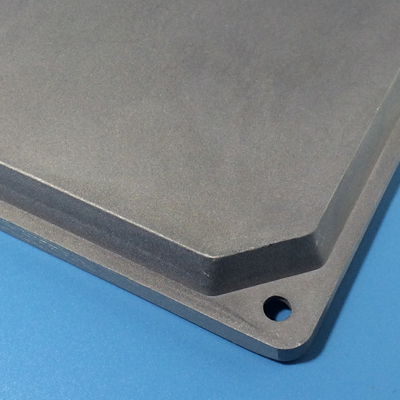

| Blank |

Anodizing |

Polishing |

Sandblasting |

| No treatment custom metal milling parts are always as a functioning part of the product. |

Anodizing finish is used for CNC milling aluminum parts |

Polishing surface treatment is normally used for CNC precision milling stainless steel parts |

Sandblasting or bead blasting are normally as a pre-treatment for the CNC milling aluminum part with the anodizing finish. |

|

|

|

|

| Color Samples |

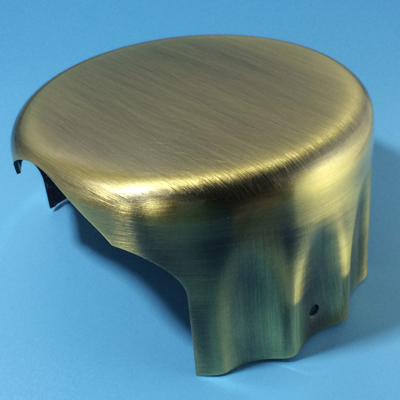

Plating |

Vacuum Plating |

Screen printing for Logo |

| Custom painting and anodizing finish for milled parts according to Panton Number |

Electroplating finish is used in steel and stainless steel milled parts & components |

Vacuum plating is used in CNC milling plastic parts |

Screen painting is used in printing custom logo, pattern on CNC milling plastic parts after UV painting |

|

|

|

|

| Rubber painting |

Powder coating |

Hot Galvanized |

Chemical Black |

| Rubber painting is used in CNC milled metal parts, make the parts feel the soft touch, specially used in CNC milled electronic product’s holder and pannel |

Powder coating is used in CNC milling aluminum or Zinc component. Outdoor or indoor use |

Galvanized surface treatment is a kind of high-grade Anti-corrosion used in steel parts that are operating at outdoor or tough working condition |

Black Oxidized and Black zinc are normally used for CNC milled metal parts such as automotive parts and auto jigs & accessories |

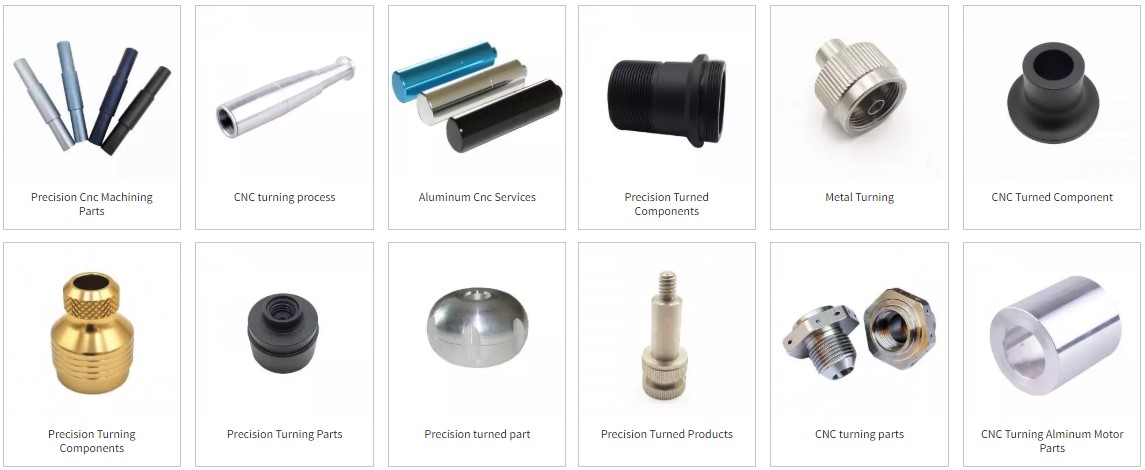

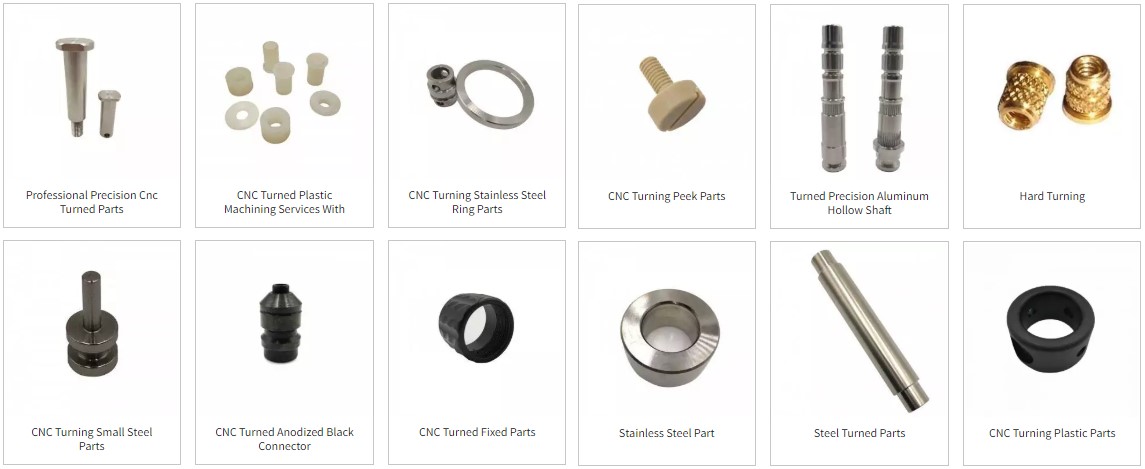

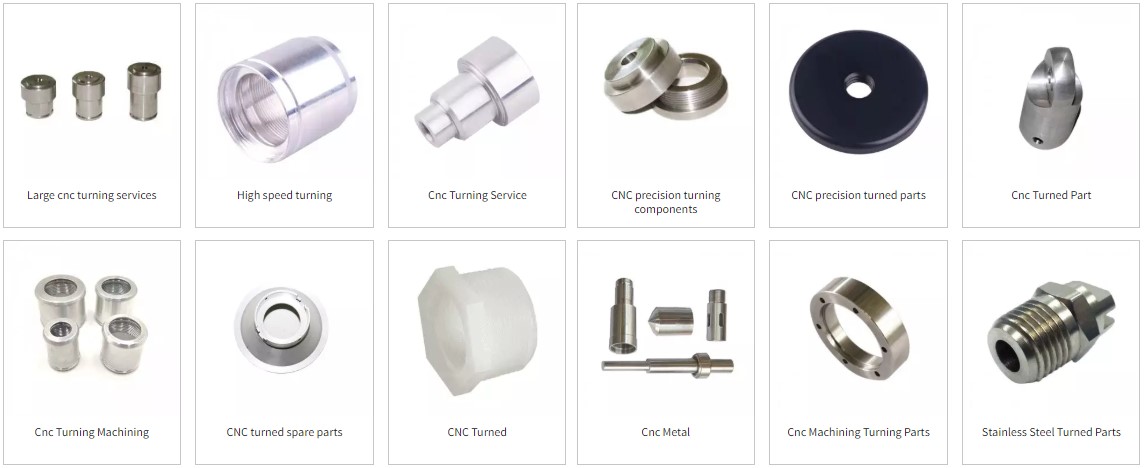

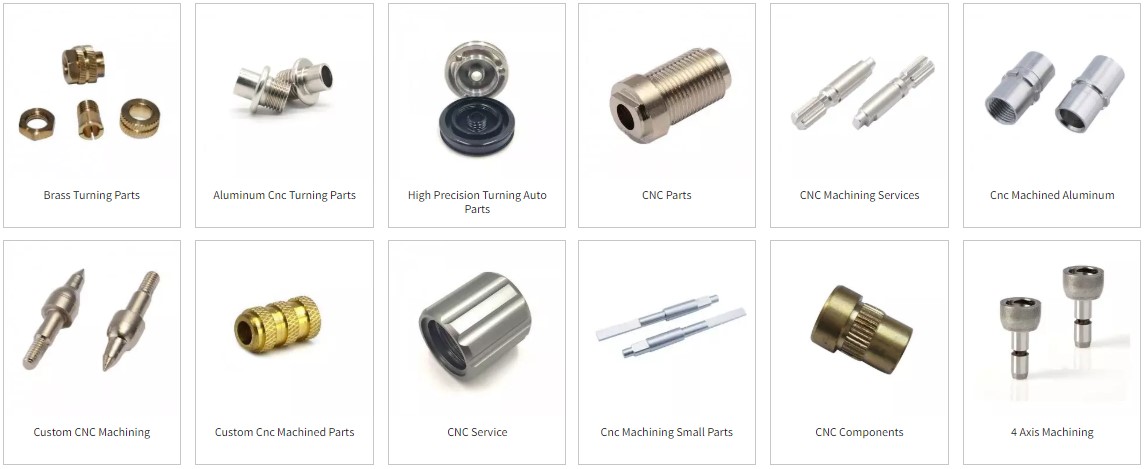

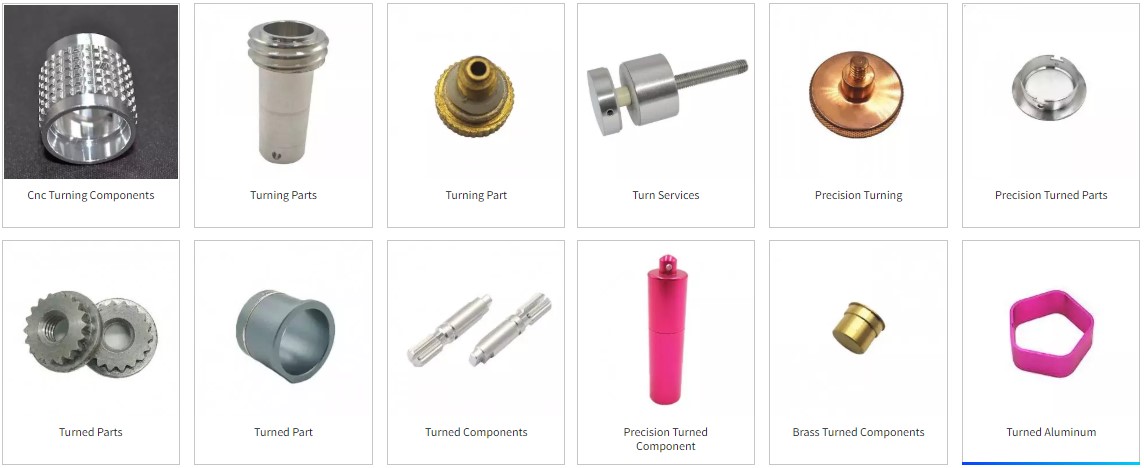

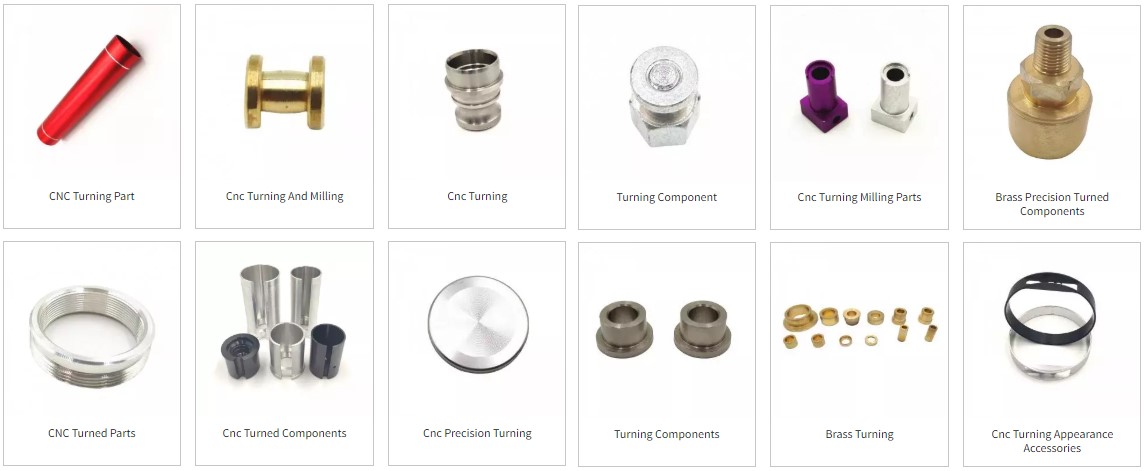

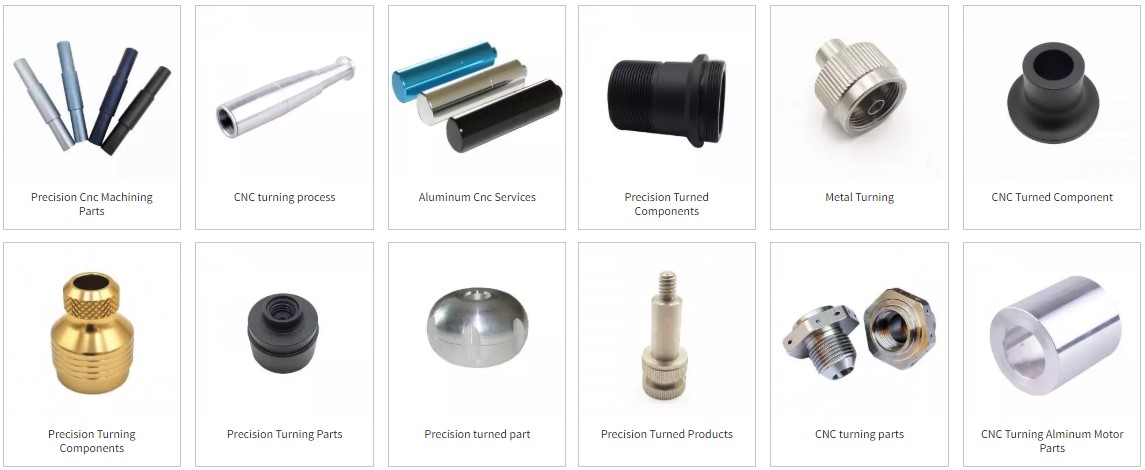

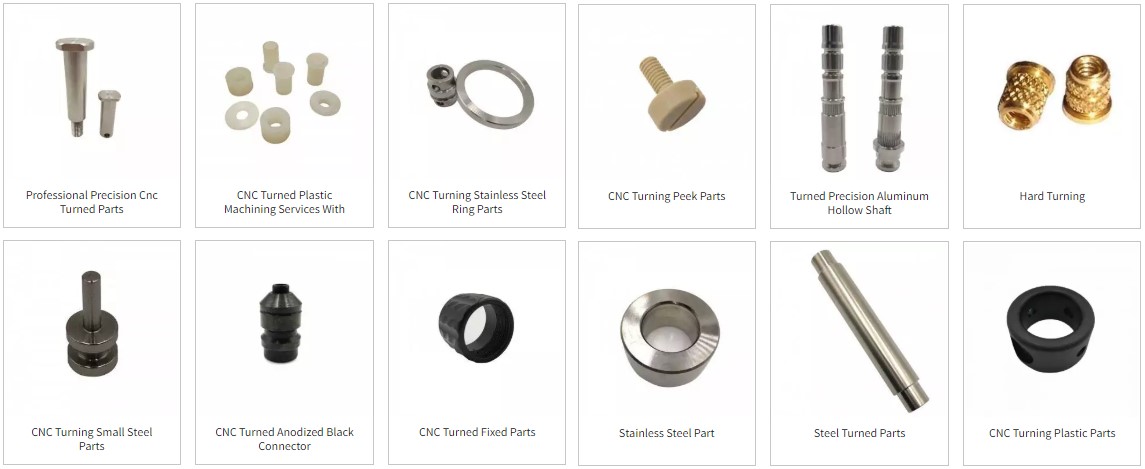

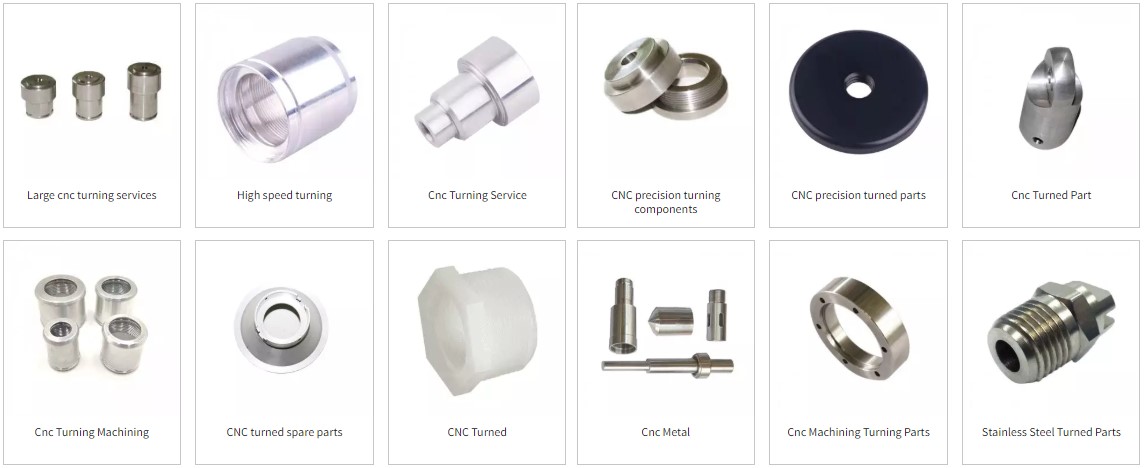

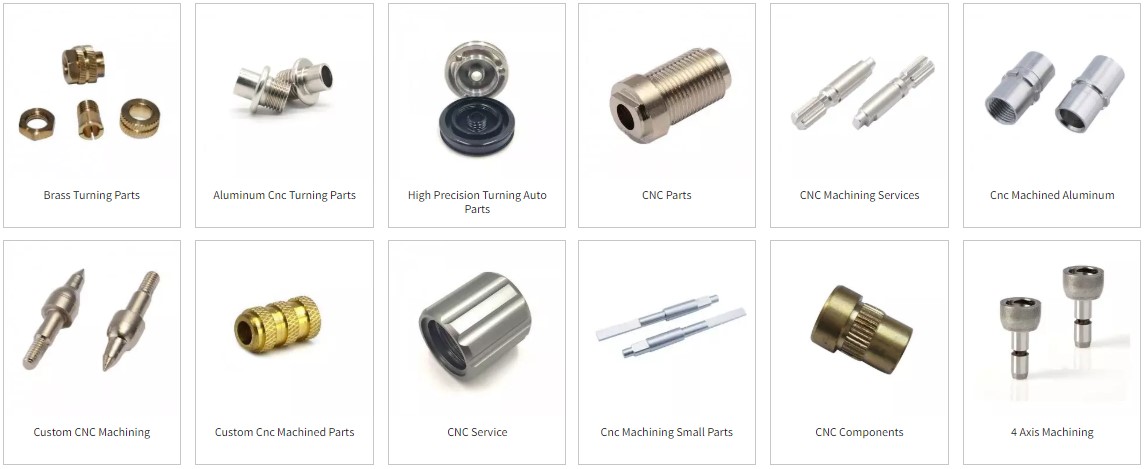

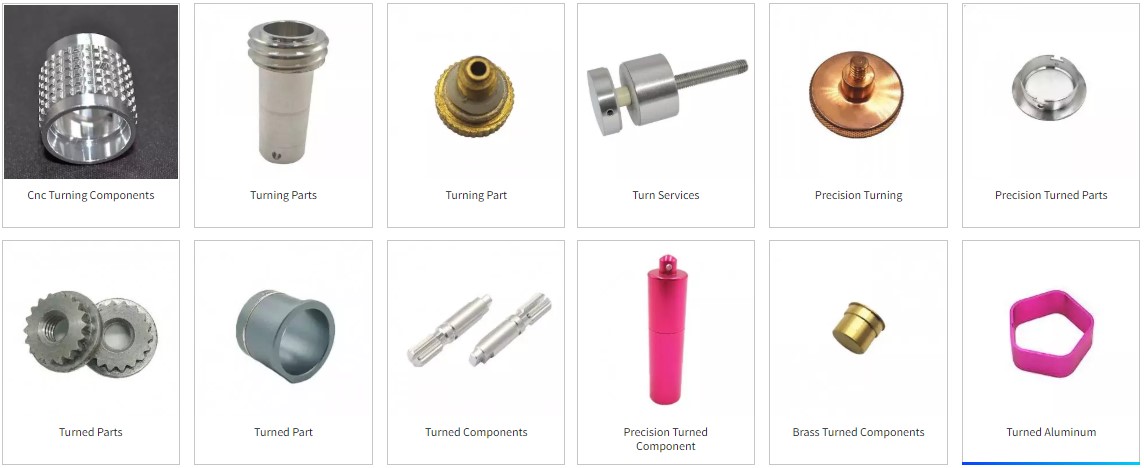

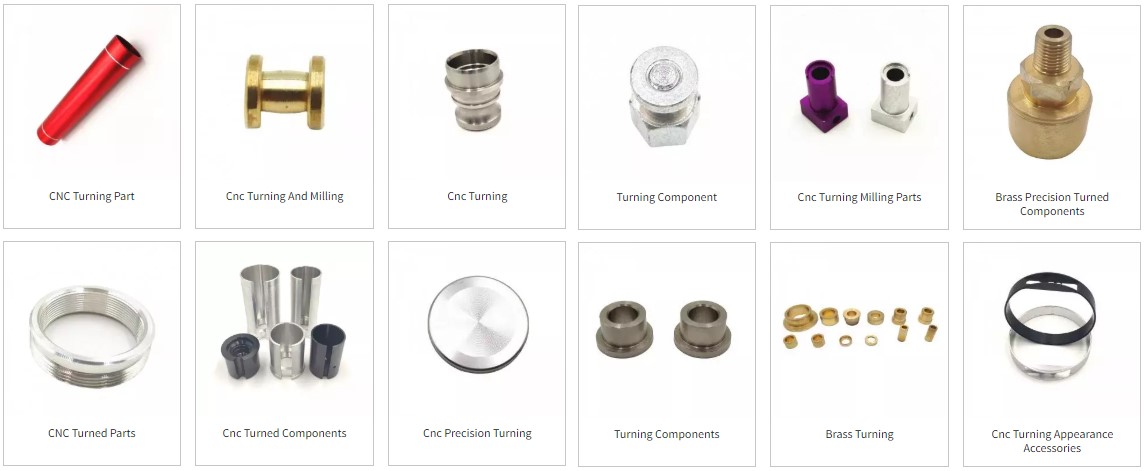

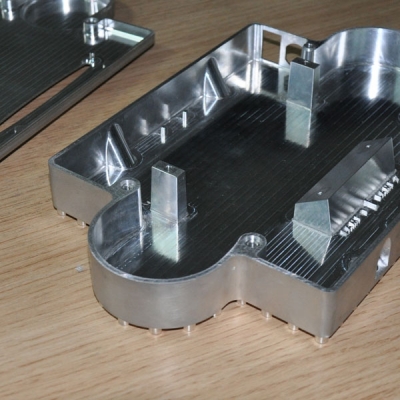

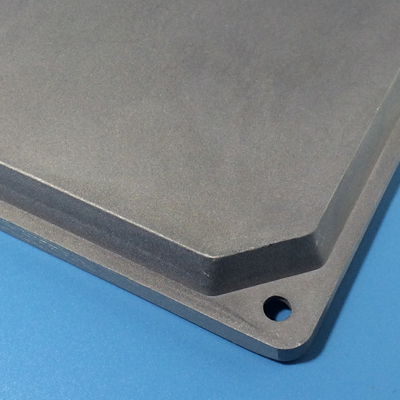

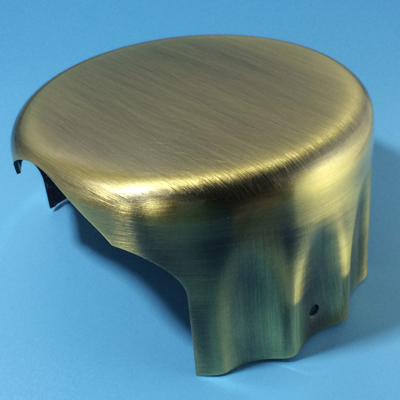

CNC turning parts we manufacture

We have produced a wide range of CNC turning parts in 10 years and our engineering team has always provided our customers with useful solutions to solve their problems in manufacturing CNC turning parts. We ensure consistently high quality machining, even in the case of complex parts, using complex machine modules and using a skilled CNC lathe to operate the machine. Because CMS always surrounds high precision!

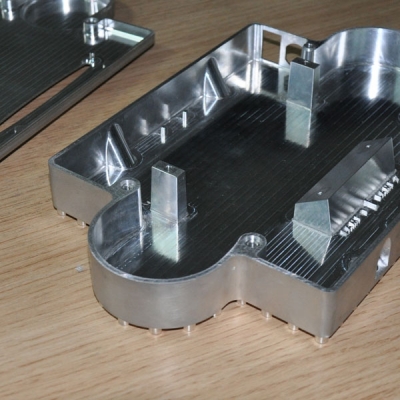

Production pictures