Thin-Film Coating

Common Thin-Film Coatings

Thin-film coatings play a prominent role on the manufacture of many electric devices. They are used to apply dopants and sealants to chips and other microelectronic parts. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are two most common types of thin-film coating methods. They are briefly discussed in this section.

Physical Vapor Deposition (PVD) Coatings: PVD coatings involve atom-by-atom, molecule-by-molecule, or ion deposition of various materials on solid substrates in vacuum systems.

Thermal evaporation uses the atomic cloud formed by the evaporation of the coating metal in a vacuum environment to coat all the surfaces in the line of sight between the substrate and the target(source). It is often used in producing thin, .5 µm (20 µin), decorative shiny coatings on plastic parts. The thin coating, however, is fragile and not good for wear applications. The thermal evaporation process can also coat a very thick, 1 mm (.040 in), layer of heat-resistant materials, such as MCrAlY — a metal, chromium, aluminum, and yttrium alloys, on jet engine parts.

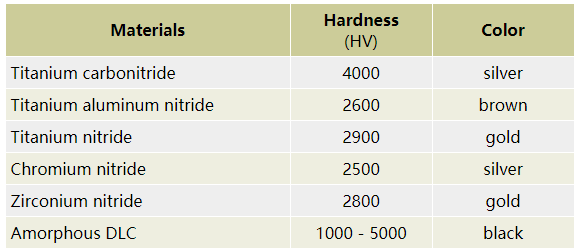

Sputtering applies high-technology coatings such as ceramics, metal alloys, organic and inorganic compounds by connecting the workpiece and the substance to a high-voltage DC power supply in an argon vacuum system (10-2 - 10-3 mmHg). The plasma is established between the substrate (workpiece) and the target (donor) and transposes the sputtered off target atoms to the surface of the substrate. When the substrate is non-conductive, e.g., polymer, a radio-frequency (RF) sputtering is used instead. Sputtering can produce thin, less than 3 µm (120 µin), hard thin-film coatings, e.g., titanium nitride (TiN) which is harder than hardest metal. Sputtering is now widely applied on cutting tools, forming tools, injection molding tools, and common tools such as punches and dies, to increase wear resistance and service life.

Chemical Vapor Decomposition (CVD) Coatings: CVD is capable of producing thick, dense, ductile, and good adhesive coatings on metals and non-metals such as glass and plastic. Contrasting to the PVD coating in the "line of sight", the CVD can coat all surfaces of the substrate.

Conventional CVD Coating process requires a metal compound that will volatilize at a fairly low temperature and decompose to a metal when it contact with the substrate at higher temperature. The most well known example of CVD is the nickel carbonyl (NiCO4) coating as thick as 2.5 mm (.1 in) on glass windows and containers to make them explosion or shatter resistant.

Diamond CVD Coating process is introduced to increase the surface hardness of cutting tools. However, the process is done at the temperatures higher than 700 ºC (1300 ºF) which will soften most tool steel. Thus, the application of diamond CVD is limited to materials which will not soften at this temperature such as cemented carbides.

Plasma-Assisted CVD Coating process can be performed at lower temperature than diamond CVD coatings. This CVD process is used to apply diamond coatings or silicon carbide barrier coatings on plastic films and semiconductors, including the state of the art .25 µm semiconductors.

Common Materials in Thin-Film Coatings