With years developing and expanding, CMS has been building good cooperation relationship with many factories in China, which enable us can provide more competitive price and better service to our customer.

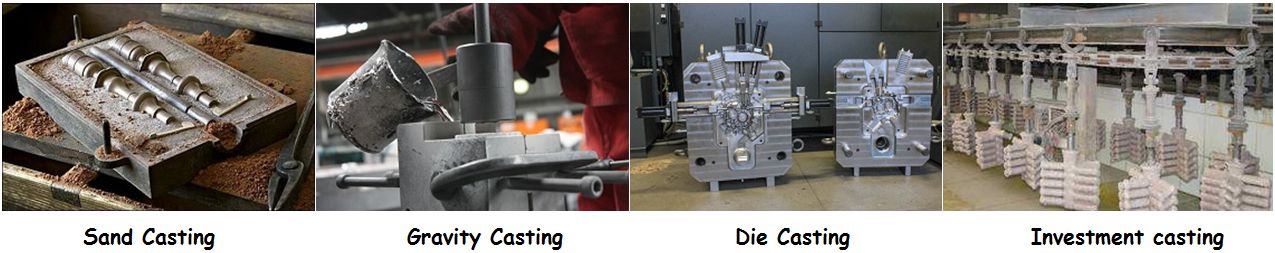

It's been more than 10 years since we started the OEM/ODM products business. By growing successfully with our customers from USA, UK, France, Germany, Japan and many other countries, we have built up a good reputation in international business and established good performance in following fields from investment casting, die casting, sand casting, and so on.

It is always our goal to provide a satisfactory service to our customer with reasonable price, high quality product, accurate delivery time and all necessary assistance.

a. Sand Casting Considering sand casting has a less cost compared with other casting processes,and fast turnaround, a lot automotive parts are choosing sand casting process,

Considering sand casting has a less cost compared with other casting processes,and fast turnaround, a lot automotive parts are choosing sand casting process,

including engine block, cylinder cover, crank shaft.Material Range: Ductile Iron, Grey Iron, Aluminum, Brass, Casting Steel, Steel Alloy...

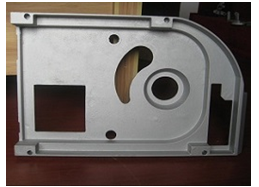

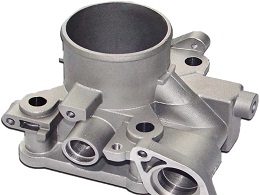

b.Die Casting

Die Casting is using high pressure to inject the melted metal into mold, it has some similarities with plastic injection molding actually. Good size control, less porosity and cheap unit price are advantages of die casting, but its tooling cost is expensive compare with other processes. Mostly we choose die casting for projects with a large volume.

Die Casting is using high pressure to inject the melted metal into mold, it has some similarities with plastic injection molding actually. Good size control, less porosity and cheap unit price are advantages of die casting, but its tooling cost is expensive compare with other processes. Mostly we choose die casting for projects with a large volume.

Material Range: Aluminum, Zinc, Brass, Magnesium, Lead and Zamak series, etc...

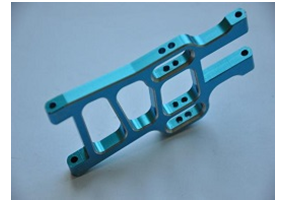

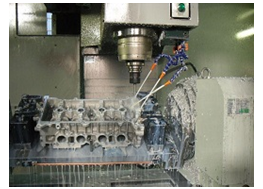

c.Gravity Casting

Gravity Casting mold are capable of million shots, also being called permanent mold casting.It is often used in medium or big size casting, plus a secondary CNC machining work.

Gravity Casting mold are capable of million shots, also being called permanent mold casting.It is often used in medium or big size casting, plus a secondary CNC machining work.

Material Range: Aluminum, Brass, Casting Steel, etc...

d.Investment casting

Investment casting also know as lost wax casting, is a manufacturing process is which a wax pattern is created and then coated with a ceramic slurry to create a mold. The wax is then melted out of the ceramic mold and molten metal is poured into the cavity. The molten metal solidifies and the ceramic shell is then broken or blasted off, creating a metal casting. The investment casting process does not require a minimum order quantity and can cast parts ranging from a few grams to upwards hundreds kgs, so it can be a manufacturing solution no matter what size project you are working on.

Investment casting also know as lost wax casting, is a manufacturing process is which a wax pattern is created and then coated with a ceramic slurry to create a mold. The wax is then melted out of the ceramic mold and molten metal is poured into the cavity. The molten metal solidifies and the ceramic shell is then broken or blasted off, creating a metal casting. The investment casting process does not require a minimum order quantity and can cast parts ranging from a few grams to upwards hundreds kgs, so it can be a manufacturing solution no matter what size project you are working on.

Typical industries served include metal casting parts for: firefighting equipment, plumbing parts, value parts, electrical hardware, precision machinery, water hydrants, gears, decorative hardware, bronze plaques, military transportation, and other industries.

a. Investment Casting Products

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|