China Manufacturing Synergy Group is a professional company specialized in making industrial products (Machining, Stamping, Plastic, Rubber, Forge ).Set up in 2008, our company has cooperated with hundreds of China manufacturers, and has more than 40 responsible employees now, including client managers (with good communication skills in English), project engineers (everyone has 5-10 year's professional job experiences), project QC(every one has 3-6 year's professional job experiences), logistics managers.

If any product development job needed, our product design and engineering team is capable of working through from your idea to mass production. This is also to cater some of our clients who has less technical background and look for one stop product development and manufacturing service.

We Make Mold Tooling In-house:

We Make Mold Tooling In-house:

As we know, mold tool is one of the most important process to make higher quality products. We had sophisticated mold makers who have over 20 years of mold making experience on various kind of mold fabrication. This is the first step to make accurate and quality parts.

At CMS manufacturing, we have mold shop in-house, which is convenient and time-saving for production. It greatly shorten our lead-time. Meanwhile, it’s easier to control the quality compared to outsourcing an molding supplier.

We understand operators are the final product producers that assemble and pack products. High-skilled operators will definitely produce higher quality products. We always encourage the plants to improve the operators’ skills. They conduct employee training by annually, quarterly, and monthly. Making sure they are qualified and in best condition for work.

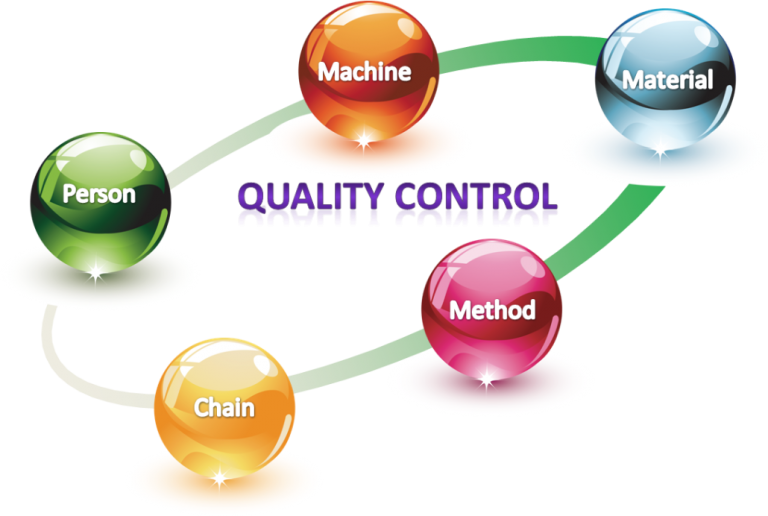

Needless to say, product quality is the most important concern for any business. We make every our effort to deliver as higher quality product as possible. We take strictly quality control from raw material to finished products. Each process are 100% controlled and monitored. If any defect product found, we can quickly track the whole process and find out root cause quickly.

Dimensional Measurement:

Dimensional Measurement:

Prior to any production, we will get our components/parts qualification by means of SPC, FA, APAP inspection process. and make sure any of our process are correctly and accurately achieved.

Normally our production engineering will outline dimensions into critical dimension, control dimension, and ordinate dimension. We focus on more energy on critical dimension and control dimension since they are fitting and function positions.

During part quality and pilot run process, our QC engineer will perform assembly and function test to check if our products are correctly produced. If any defects found, we will initiate correction plan immediately.

Before shipping, our process QA inspector will perform 100% of final products. it greatly avoid any unnecessary lost and waste of time. So that our clients will receive zero defects rate products.

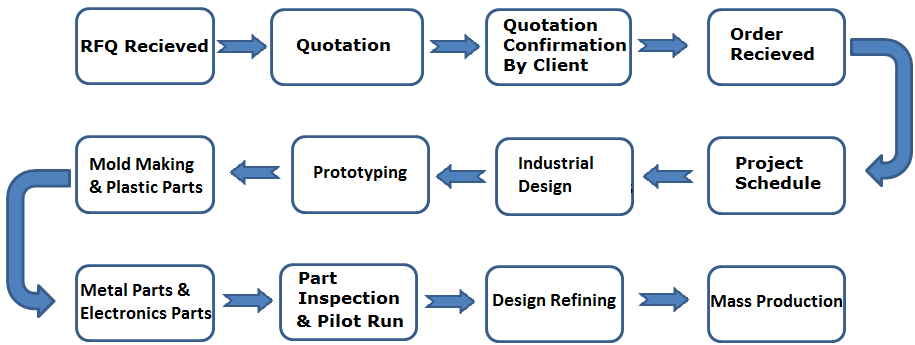

Step by step from design, engineering, prototyping, pilot run, until mass production

Step by step from design, engineering, prototyping, pilot run, until mass production

Our engineers work carefully and systematically from product design, engineering, prototyping, pilot run, until mass production. It’s a practical measure to prevent projects from risks and avoid unnecessary mistakes to happen.

We understand engineering is a scientific process. any of our work process must be traceable and controllable. We get all of engineering drawing, material, sample recorded and restored. If any thing changed, our documentation staff will release relative document to notify people who are related to .

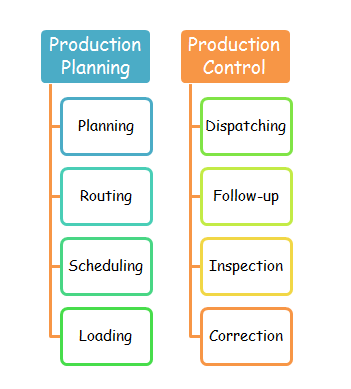

Project management is one of the most important process to deliver quality products, to deliver our manufacturing excellence, we have most sophisticated project managers and project engineers who has over ten years of experience on project management. With a target of result and time-oriented, we plan, schedule, and follow up each project from begin to end. Making sure every our project on time, on track, and on budget.