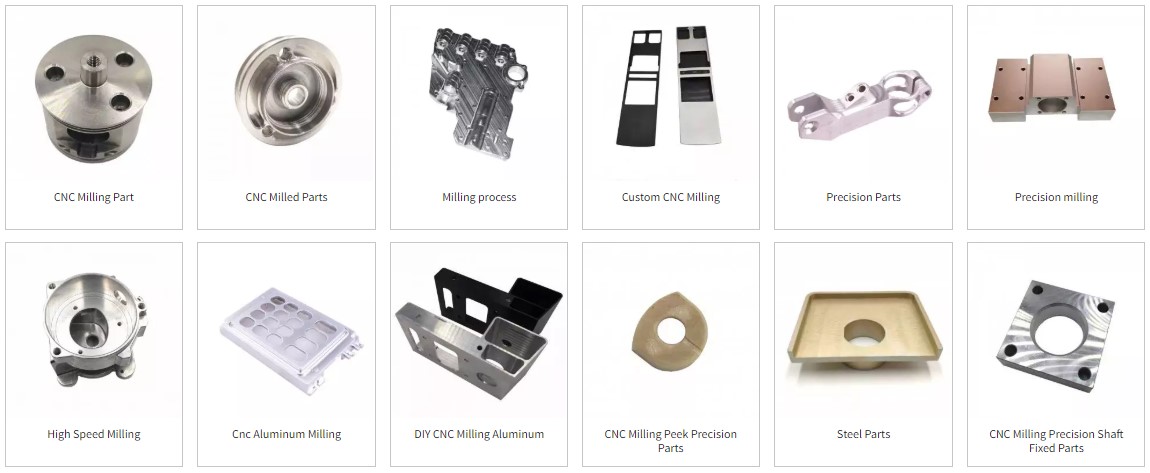

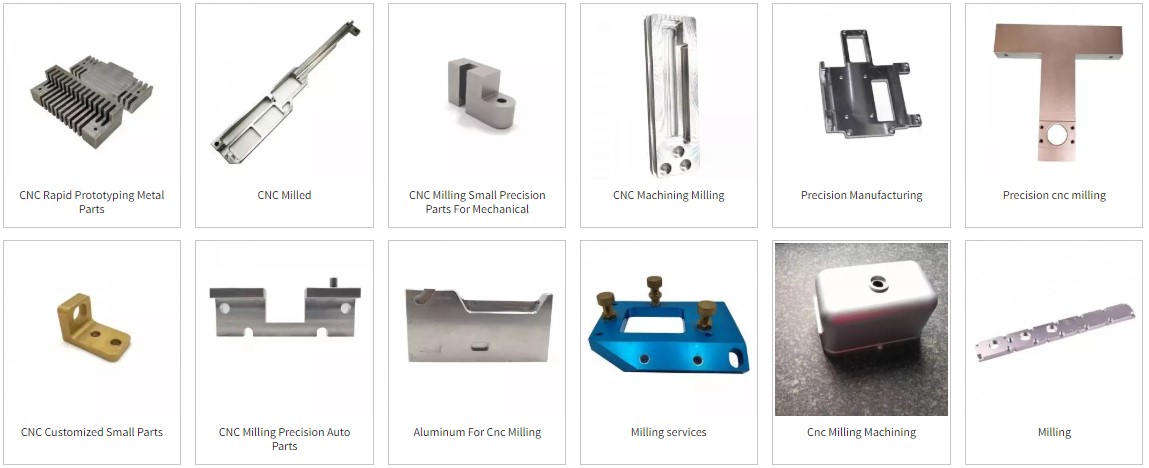

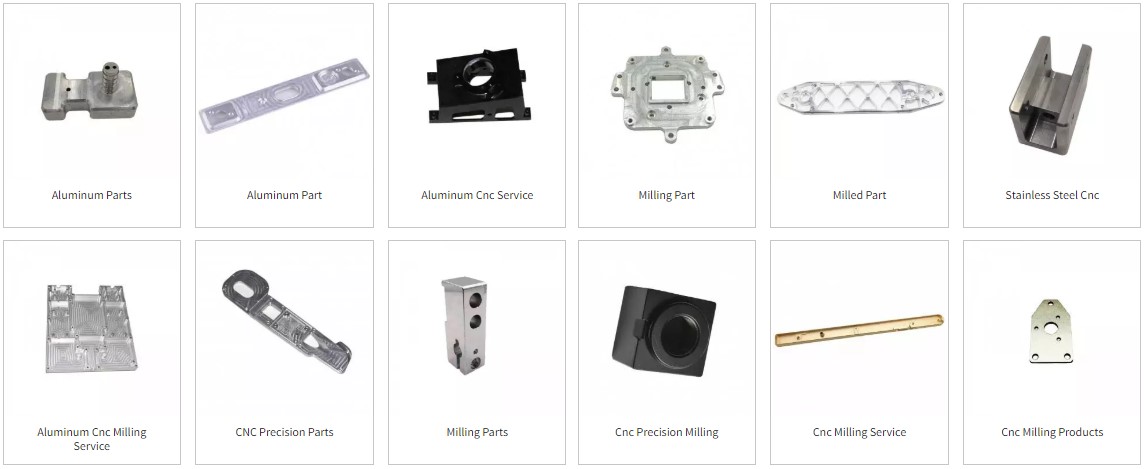

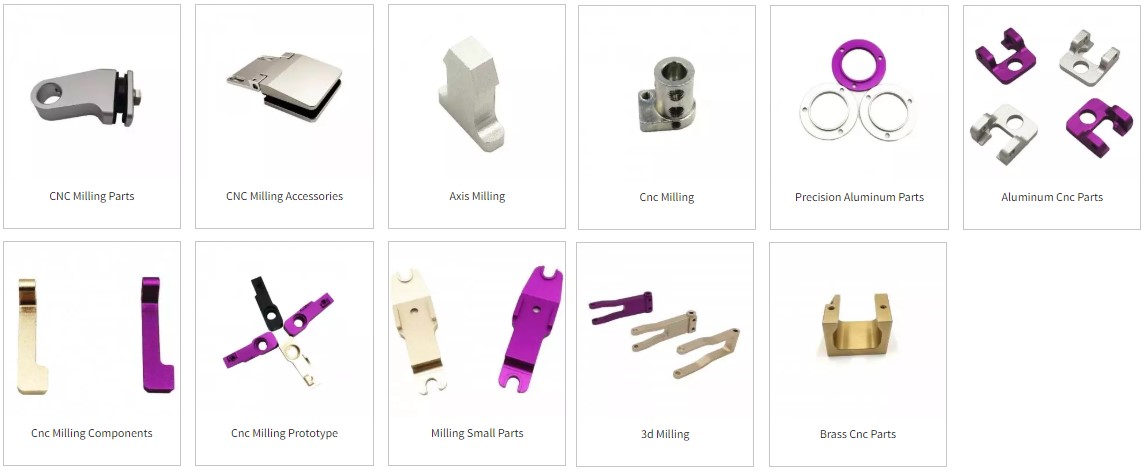

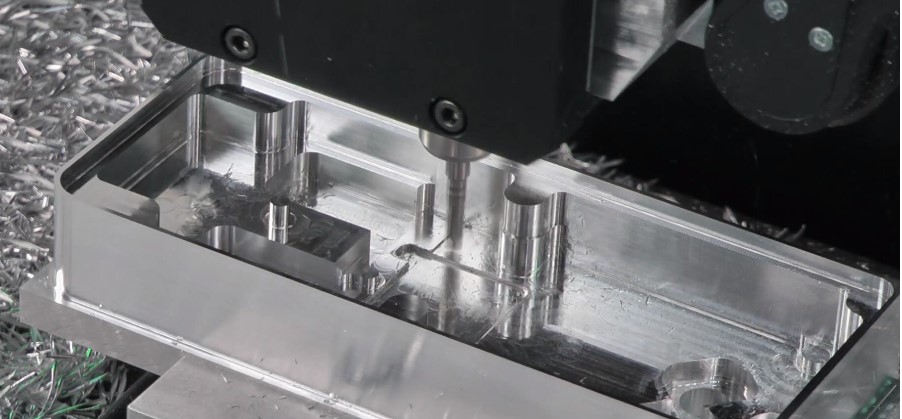

At CMS, we operate a wide range of state-of-the-art CNC milling machines offering a wide range of machining services, including precision milling. We are proud to have CNC machining capabilities to handle projects of all sizes. Through these milling machines, we are able to provide capabilities to a range of industry leaders in the market. Our milling services have multiple CNC milling machines, and our products are often used in the automotive, aerospace, medical, 5G communications, marine, consumer electronics, renewable energy and other industries.

At CMS, we operate a wide range of state-of-the-art CNC milling machines offering a wide range of machining services, including precision milling. We are proud to have CNC machining capabilities to handle projects of all sizes. Through these milling machines, we are able to provide capabilities to a range of industry leaders in the market. Our milling services have multiple CNC milling machines, and our products are often used in the automotive, aerospace, medical, 5G communications, marine, consumer electronics, renewable energy and other industries.

What is the process of computer numerical control milling?

CNC milling uses a rotary cutting tool similar to drilling, except that one tool moves along different axes to form a variety of shapes, including holes and slots. It is a common form of CNC machining because it performs the functions of drilling and latheing. This is the easiest way to drill holes for all types of premium materials to produce the right product for your business.

Precision milling and efficient CNC systems

With our spindle coolant supply, we can cut materials faster than standard coolant spray systems, and our CAD / CAM, UG and Pro/e, 3D Max. can more effectively interact with customers technically and greatly Accelerate the entire process and provide you products with high efficient. Our two horizontal CNC milling centers feature automatic steering knuckles that allow us to machine at any angle. Together with the use of spherical tools, this allows us to achieve the same complex geometry as any five-axis machine.

5-AXIS CNC Milling Capacity

When mentioned a standard 5-axis machine, it refers to the number of directions in which the cutting tool can move, that after setup the cutting tool moves across the X, Y and Z linear axes and rotates on the A and B axes, simultaneous milling and machining, and with high-quality surface machined finish. This allows the complex and intricate parts or parts featuring multiple sides can be processed up to five sides of a part in a single setup. This supports design engineers to design multifaceted parts that can enhance the functionality and performance of the final product without limited process.

When mentioned a standard 5-axis machine, it refers to the number of directions in which the cutting tool can move, that after setup the cutting tool moves across the X, Y and Z linear axes and rotates on the A and B axes, simultaneous milling and machining, and with high-quality surface machined finish. This allows the complex and intricate parts or parts featuring multiple sides can be processed up to five sides of a part in a single setup. This supports design engineers to design multifaceted parts that can enhance the functionality and performance of the final product without limited process.

Advantages of 5-Axis CNC Milling

High-quality surface finish: It is feasible to produce high-quality machined finish parts with the use of shorter cutters with a higher cutting speed, which can reduce the vibration that frequently occurs when machining deep cavities with a 3-axis process. It makes a smooth surface finish after machining.

Positioning accuracy: 5-axis simultaneous milling and machining has become crucial if your finished products must adhere to strict quality and performance specifications.5-axis CNC machining also eliminates the need to move the work piece among multiple workstations, thereby reducing the risk of error.

Short lead times: The enhanced capabilities of the 5-axis machine results in decreased production times, which translate into shorter lead times for production compared to the 3-axis machine.

Some common tool shapes include:

• Ordinary end mills - Walls with straight 90 degree edges and sharp corners at the bottom of the groove.

• Chamfer end mill - Forms a 45 degree bevel on the top edge of the wall or groove

• Slotted end mill - Forms a rectangular groove on the side wall

• Ball Mill - Forms a rounded edge at the bottom edge of the groove

• Round end mill - Creates a rounded edge at the top edge

• Angle end mill - Create walls at angles other than 90 degrees

• Traditional drill bit

Material

Metal: aluminum, stainless steel, copper, steel, brass, titanium, sterling silver, bronze, etc.

Hard plastics and other materials: nylon, acetal, polycarbonate, polystyrene, acrylic, fiberglass, carbon fiber, Teflon, ABS, PVC, etc.

Product