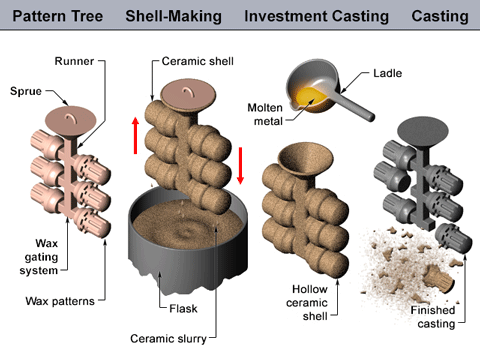

Investment casting also know as lost wax casting, is a manufacturing process is which a wax pattern is created and then coated with a ceramic slurry to create a mold. The wax is then melted out of the ceramic mold and molten metal is poured into the cavity. The molten metal solidifies and the ceramic shell is then broken or blasted off, creating a metal casting. The investment casting process does not require a minimum order quantity and can cast parts ranging from a few grams to upwards hundreds kgs, so it can be a manufacturing solution no matter what size project you are working on.

Benefits Of Investment Casting

The advantage of investment casting are impressive. Creat almost any configuaration of your precision metal component. Design parts as small, large, or complex as you need. In short, eliminate many of the barries holding you back today.Investment casting can also help you:

--Reduce secondary operations

--Create stronger parts

--Have the widest choice of alloys

--Produce less waste

--Maintain incredibly tight tolerances

--Incorporate thinner walls for reduced weight

--Maintain outstanding repeatability

--Reduce tooling costs over multiple production runs

--Design highly detailed surfaces and stamps

Investment Casting Process

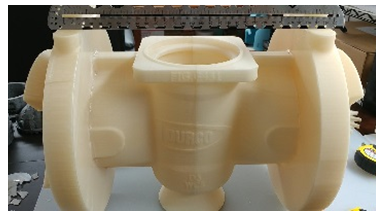

1.Die Construction & Building

To pursue of precision investment casting, a metal die/master die is the first step. The size of the master die must be carefully calculated, it must take into consideration expected shrinkage of the wax pattern, the expected shrinkage of the ceramic material invested over the wax pattern, and the expected shrinkage of the metal casting itself. Using CNC machining and wire EDM to build a precision mold.

To pursue of precision investment casting, a metal die/master die is the first step. The size of the master die must be carefully calculated, it must take into consideration expected shrinkage of the wax pattern, the expected shrinkage of the ceramic material invested over the wax pattern, and the expected shrinkage of the metal casting itself. Using CNC machining and wire EDM to build a precision mold.

2. Wax Pattern Production  Hot wax is injected into the mold or die and allowed to solidify. Cores may be needed to form any internal features. The resulting wax pattern is an exact replica of the part to be produced. The method is similar to die casting, but with wax used instead of molten metal.

Hot wax is injected into the mold or die and allowed to solidify. Cores may be needed to form any internal features. The resulting wax pattern is an exact replica of the part to be produced. The method is similar to die casting, but with wax used instead of molten metal.

3. Shell Creation

A gating system(sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, serveral wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the ruuner bars, serves to lead molten metal into the mold.

A gating system(sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, serveral wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the ruuner bars, serves to lead molten metal into the mold.

The assembled "pattern tree" is dipped into a slurry of fine-grained silica. It is dipped repeatedly, being coated with progressively more refractory slurry with each dip. Once the refractory coating reaches the desired thickness, it is allowed to dry and harden, the dried coating forms a ceramic shell around the patterns and gating system. The hardened ceramic mold is turned upside down, placed in an oven, and heated until the wax melts and drains away. The result is a hollow ceramic shell.

4. Pouring  The ceramic mold is heated to around 550-1100°C. The heating process further strengths the mold, eliminates any leftover wax or contaminants, and evaporates water from the mold material. Molten metal is poured into the mold while it is still hot - liquid metal flows into the pouring cup, through the central gating system, and into each mold cavity on the tree. The pre-heated mold allows the metal to flow easily through thin, detaled sections. It also creates a casting with improved dimensional accuracy, as the mold and casting will cool and shrink together.

The ceramic mold is heated to around 550-1100°C. The heating process further strengths the mold, eliminates any leftover wax or contaminants, and evaporates water from the mold material. Molten metal is poured into the mold while it is still hot - liquid metal flows into the pouring cup, through the central gating system, and into each mold cavity on the tree. The pre-heated mold allows the metal to flow easily through thin, detaled sections. It also creates a casting with improved dimensional accuracy, as the mold and casting will cool and shrink together.

5. Dry Out

After the mold has been poured, the metal cools and solidifies. The time it takes for a mold to cool into a solid state depends on the material that was cast and the thickness of the casting being made. The hang in the wax tree and dry out.

After the mold has been poured, the metal cools and solidifies. The time it takes for a mold to cool into a solid state depends on the material that was cast and the thickness of the casting being made. The hang in the wax tree and dry out.

6. Shake Out

Once the casting solidifies, the ceramic molds break down, and the casting can be removed. The ceramic mold is typically broken up manually or by water jets. Once removed, the individual casting are separated from their gating system tree using manual impact, sawing, cutting, burning, or by cold breaking with liquid nitrogen.

Once the casting solidifies, the ceramic molds break down, and the casting can be removed. The ceramic mold is typically broken up manually or by water jets. Once removed, the individual casting are separated from their gating system tree using manual impact, sawing, cutting, burning, or by cold breaking with liquid nitrogen.

7. Heat Treatment  This is to improve the mechanical properties of investment castings, we can do heat treatment service including: normalizing, tempering, annealing, hardening and carburizing, etc.

This is to improve the mechanical properties of investment castings, we can do heat treatment service including: normalizing, tempering, annealing, hardening and carburizing, etc.

8. Blasting & Secondary Operation

After finish castings and heat treatment if required, blasting surface is a must for castings. We can also offer secondary operations which are CNC machining and surface plating, such as anti-rust oild protection, painting, plating.

After finish castings and heat treatment if required, blasting surface is a must for castings. We can also offer secondary operations which are CNC machining and surface plating, such as anti-rust oild protection, painting, plating.