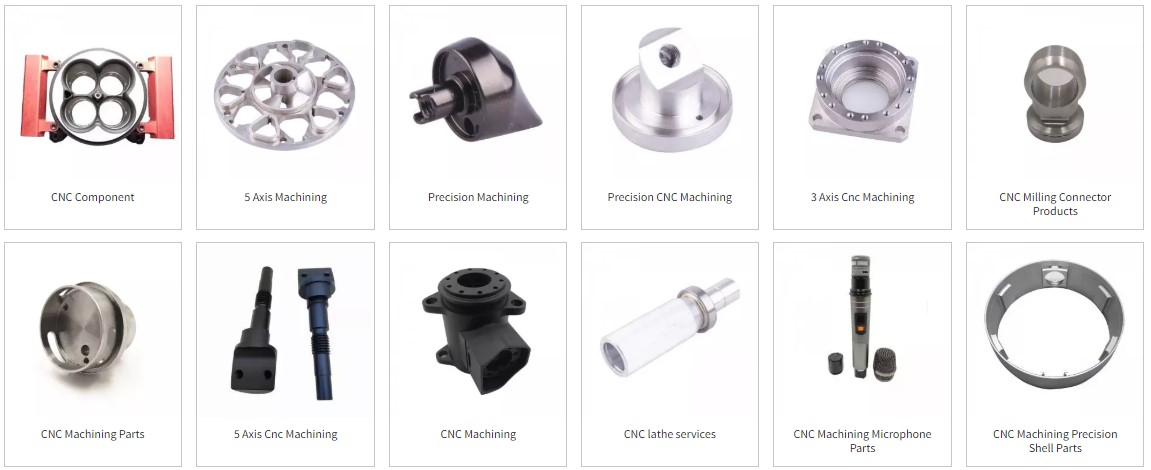

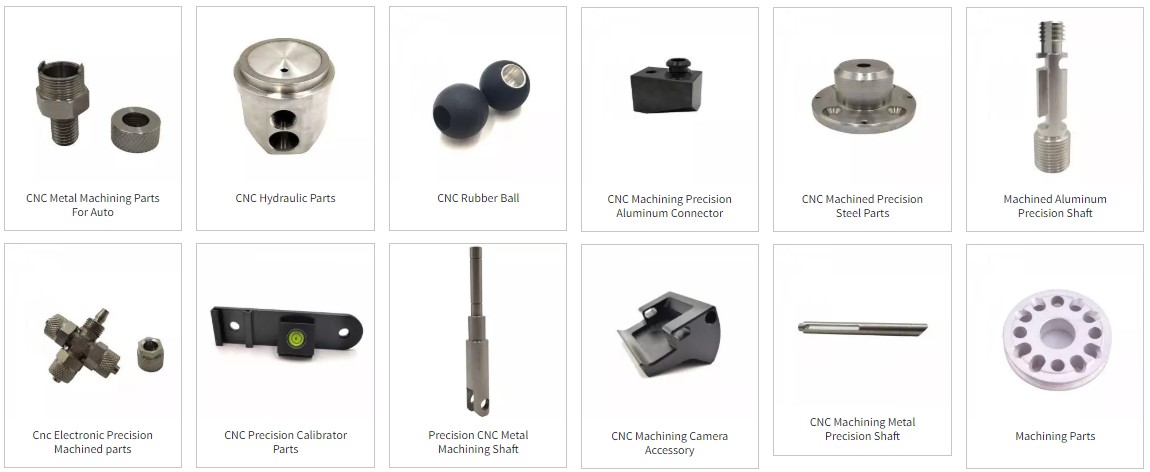

CMS CNC machining service

CMS can offer advanced equipment to provide you with a wide range of CNC machining services, including milling, turning, EDM, wire cutting, surface grinding and more. We use imported 3, 4 and 5-axis CNC machining centers to offer you great precision, amazing flexibility, and a decent output for almost any machining project. We not only have different machines, but also a team of experts, who are committed to providing you with the best-in-class service in China. We have skilled mechanics which can use a variety of plastic and metal materials to produce turning and milling parts.

We assure you that no matter the size of the job, our professionals treat it as if it were their own. We can also provide prototype CNC machining services that would help you in getting a clear picture of the final product.

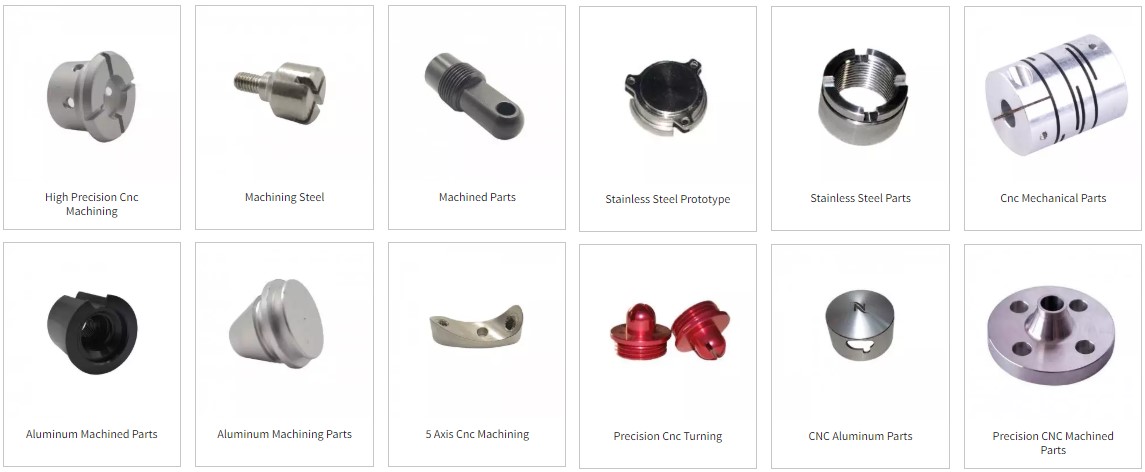

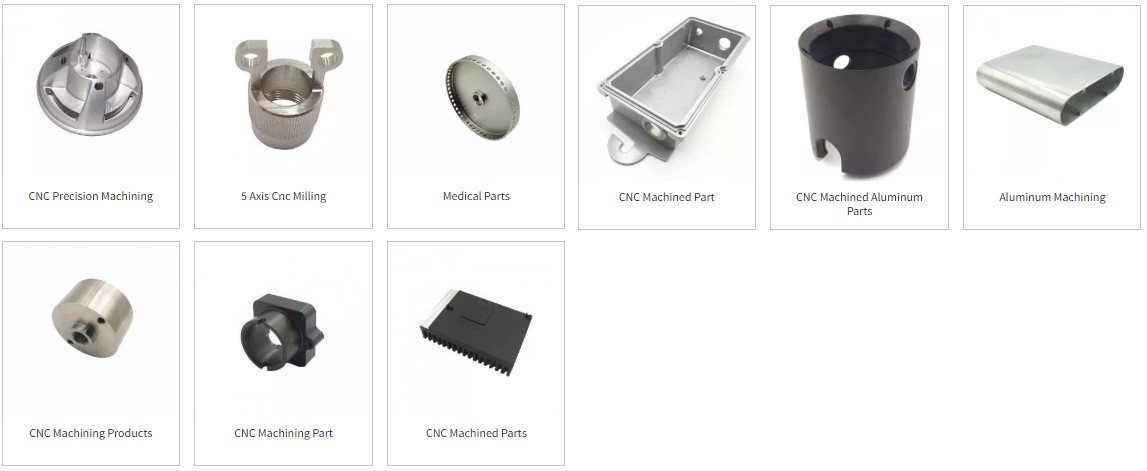

Advantages of CNC machining

CNC machining is ideal for your range of product development needs. Here are some of the advantages of precision machining:

• Quickly remove large amounts of metal material

• Highly accurate and repeatable

• Suitable for many different types of substrates

• Low investment in mold and preparation costs

• Economy

• Mold design and manufacturing

• Mechanical processing of titanium alloys, superalloys, non-metals, etc.; mold design and manufacturing

• Non-standard equipment design and manufacture

• Machining process: drilling, thread milling, broaching, tapping, spline, reaming, cutting/cutting,

Profile, finish, turning, threading, internal forming, dimples, knurling, countersunk, boring, reverse drilling, hobbing

• Tolerance: ±0.002mm

Material

Steel |

Carbon Steel, 4140,20#, 45#, 4340, Q235, Q345B, etc |

Stainless Steel |

SS303, SS304, SS316, SS416 etc. |

Aluminum |

Al6063, AL6082, AL7075, AL6061, AL5052, A380 etc. |

Iron |

12L14, 1215, 45#, A36, 1213, etc. |

Brass |

HSn62-1, HSn60-1, HMn58-2, H68, HNi65-5, H90, H80 , H68, H59 etc |

Copper |

C11000, C12000, C12000, C26000, C51000 etc. |

Plastic |

Delrin, Nylon, Teflon, PP, PEI, ABS, PC, PE, POM, Peek.Carbon Fiber |

Surface Treatment

Mechanical Surface Treatment |

Sand blasting, Shot Blasting, Grinding, Rolling, Polishing, Brushing, Spraying, Painting, Oil Painting etc. |

Chemical Surface Treatment |

Bluing and Blackening, Phosphating, Pickling, Electroless Plating of Various Metals and Alloys etc. |

Electrochemical Surface Treatment |

Anodic Oxidation, Electrochemical Polishing, Electroplating etc. |

Modern Surface Treatment |

CVD, PVD, Ion implantation, Ion Plating, Laser Surface Treatment ect. |

Sand Blasting |

Dry Sand Blasting, Wet Sand Blasting, Atomized Sand Blasting etc. |

Spraying |

Electrostatic Spraying, Fame Spraying, Powder Spraying, Plastic Spraying, Plasma Spraying |

Electroplating |

Copper Plating, Chromium Plating, Zinc Plating, Nickel Plating |