A good product must start with a successful product design and mold design. Collaborate with Ego Manufacturing Group could avoid lengthy delays in getting your product into the market place. We can provide a tailored service to meet your expectations within the agreed timeframe and price point.

A good product must start with a successful product design and mold design. Collaborate with Ego Manufacturing Group could avoid lengthy delays in getting your product into the market place. We can provide a tailored service to meet your expectations within the agreed timeframe and price point.

We can enable any idea to be transformed into tangible and viable outcomes. We have the knowledge to take client concepts and turn them into a commercially usable product. Ego Manufacturing Group has developed products for a wide range of industries and dealing with critical product elements such as complex forms, dimensions, tolerances, finishes and materials are standard practise within our business.

We work collaboratively with our clients to understand the specific requirements, needs and philosophy ensuring a successful outcome.

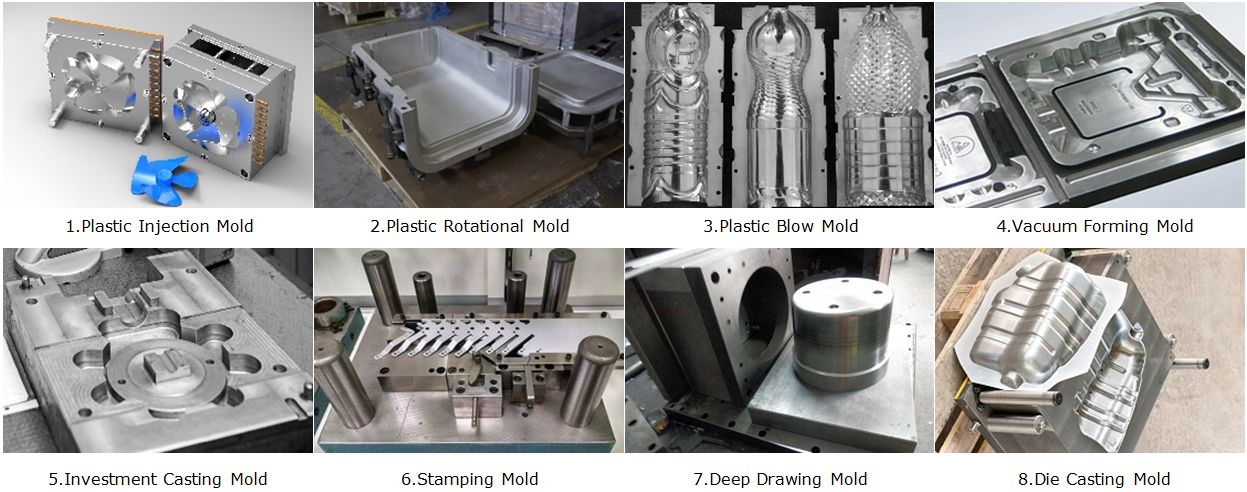

Classification of molds

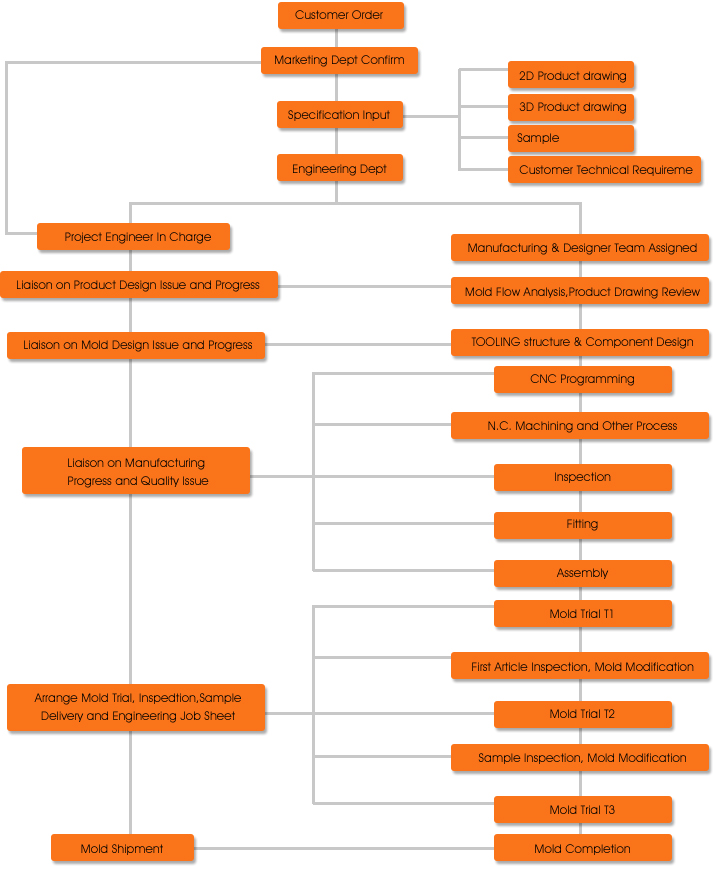

Mold Design Process

1.Purchase order and deposit payment received from the client

2.Sales team hand over all information to the design team

3.Design debrief

4.Process sequence agreed

5.Design milestone dates agreed with our client

6.Preliminary design scoped up

7.Meeting with client to review prelimiary design, agree on changes

8.Design process continues

9.Meeting with client to sign off on final design

10.Agree on final changes

11.Final meeting to sign off the design

12.Tool released for manufacture

Mold Development&Fabrication

Quality control

CMS always puts the quality in the first place. To meet customer’s requirements and expectation, we manage the quality of tooling and goods by the advanced measurement facilities, under the advanced and complete quality control system, with the scientific methods of quality control. Quality control plan is made when the case of tooling or goods launched, and it will always monitor every stage of the production course. Moreover, when the electrode and unit part are finished, CPK test will be run and its data will be as the criteria for mold check and acceptance internally. Throughout the production, material for product is inspected by IQC the moment it is delivered to factory. If the material doesn’t meet the requirements, it will be rejected immediately. Warehouse only accept the qualified one. During production, goods on the line are checked by IPQC regularly. Only the goods examined by QA to be qualified will be delivered to customers.

Precision tool & die makers for any project, big or small, Contact to get your project started now.