Over the years, there have been a number of processes that are used to make metal parts, most popular being machining and produced by die casting mold/tooling. Because of massive demand in the industrial and private sectors, we have continued to invest in state of the art machinery and innovative processes to deliver products you can depend on.

We specializing in aluminium die casting, magnesium die casting, zinc die casting and other metals, we have highly skilled staff that employ superior tooling and high pressure die casting processes to ensure that the parts are of the highest quality and are cost-effective. Our processes are precise and consistent to ensure that our return clients get the same high-quality products all year round.

With a combination of manual process monitoring by our experts and automation, any flaws in the processes are quickly detected and corrected to ensure we get the right finish, product integrity and minimize any eventual wastes. You can rest assured that the end product will not only be time-efficient but will also provide a return on your investment.

In the industrial sector, our die casting services include the manufacturing of air compressors, industrial pumps, led light housing, and piston connecting rods among several other types of equipment. Whichever product we manufacture, we ensure consistency in performance, strength, and cost-effectiveness.

We understand the essence of having loyal customers and to make sure of this, we provide the best services & prices in the market. We work tirelessly to ensure that our team produces premier products of high quality and the expectations of clients exceeded with every single order. If you are looking for consistency, quality, cost-effectiveness, and innovation, Aluminum Die Casting or Magnesium/zinc die casting mold and parts, then we are your go-to company.

If you have a project that needs plastics and metal parts service, you are come to the right place, we have rich experience in plastic mold, stamping tooling, die casting mold/tools. Contact our expert team and get a price for your die casting tooling project, we will quote you a price in 24 hours.

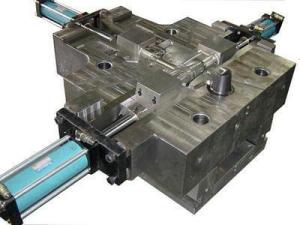

die casting tooling

Aluminium die casting mold

Die casting China

Die Casting manufacture company

High Pressure die casting parts

Die-casting is a process of manufacturing that can produce complex aluminum, zinc or magnesium metal alloy parts through reusable molds known as the dies, or die casting tool (mold). The process involves the use of metal, furnace, machine, and the die casting tooling itself. When it comes to aluminum of this kind, one needs to continuously change, innovate, and grow with the changing pace of the innovative scenarios. With skilled professionals and sound practices, the premium manufacturers win the battle. The clients prefer the ones with extended warranties, superior warranties, and improved durability.

The origin of die casting can be traced back to the 19th century, the record has shown the earliest die casting machine was invented in 1838 purposely to be used in manufacturing parts for movable machines used in the printing industries, precisely 11 years after the first die casting related patent was granted and the first beneficiary of the die casting process happened to be the printing industry

By the early 20th century, die casting has made a great leap forward because the metal foundries were already making use of aluminium alloys and zinc for die casting. After a few decades, the copper and magnesium were introduced into the die casting process

Refinement

The die casting processes has certainly gotten refined and improved since then, but it still maintains the same general elements, which means the molten aluminum or zinc alloy (metal) is still poured into a closed die casting tool and allowed to cooled and solidified before being ejected.

Later In the middle of1960’s. General Motors formed its own die casting process which successfully cast low aluminum alloys.

They used these casts to make parts for their line of vehicles.

LED street light housing

LED light frame casting

LED light housing

Modern Days

Today, there has been tremendous improvement in the die casting process, men have successfully found ways to cast faster, coming out with a better surface finish as can be seen in many of today’s high pressure die casting.

The history of die casting may be short, but the process has evolved a lot from the days of low-pressure injection when limited metals like lead, tin and other variants are being used. so far with the long transitioning of the process, we can conclude that the die casting has come to stay and it will keep improving.

The Useful Element

Aluminium is the third most fruitful element on earth as it is incredibly versatile that can be made into a wide range of diverse and useful products, which is known to as the aluminium die casting. This process involves the melting of an aluminum alloy, which is heated up to 1400 degrees Fahrenheit. The molten aluminium alloy will be poured into a die casting mold until it is fully filled. Once the aluminum material is cooled in the die-cast tool and it is removed by the ejection system. Most frequently, this casting process involves power coating, anodizing, polishing and grinding to make it a fully functional product.

What Makes It Different

The die casting aluminum parts of this kind are even stronger as compared to the steel. To make sure of the quality of die casting parts, it is important to make the DFM report from designing, to check any possible issue in advance. They are responsible roles towards the final product. Assembling and testing of the finished products are done to maximize productivity and ensure getting a satisfactory output. The process of engineering needs to be reliable and economical to match up with various clients as well as their demands.

With the procedure referred to as gravitational force die-casting, the mold additionally called a ‘die’ is produced from high-quality steel, and also could be utilized many times. This implies that the die casting tooling is very expensive, compared to an expendable ‘one usage simply’ mold. An intermediate strategy takes advantage of semi-permanent molds, which are made from gypsum plaster or fire clay or sand casting mold, which could be made use of repetitively for a restricted variety of castings. With this procedure, one of the most favored products for die-castings is cast iron, steel, as well as warmth withstanding alloys of iron.

To avoid the casting steel from staying with the die, the die casting mold could be provided an interior coating of chalk, clay, or bone ash with water glass as a binder. This mix could be put on the tooling by using, cleaning or immersion. With easy castings, the liquefied steel could be gathered on top. It should be developed to permit the liquefied steel to stream swiftly without disturbance right into all components of the die. For steels with reduced melting aims the die is in some cases warmed to stop untimely solidification, and also for steels with a high melting factor, the die could need to be synthetically cooled down after each casting operation.

High Die-casting product is less costly compared to the sand castings, but the die casting tooling is more expensive than the sand casting mold, as well as a maximum number of castings require to be created to make the procedure expense reliable

Advantage of Die Casting process

1), Very high rates of production are possible, in cold chamber type 75 to 150 units per hour and in hot chamber type 300 to 350 units per hour.

2), High precision dimensional control can be maintained, in zinc, a tolerance of +/- 0.075 mm up to 25 mm size and +/- 0.025 mm for each additional 25 mm can be easily achieved.

3), Thin section can be cast; under favorable conditions, minimum thickness cast is about 0.5 mm for zinc and 0.8 mm for aluminum alloy.

4), the Surface finish of 1250 micro-mm R.M.S can be obtained hence appearance is improved and finishing operation is minimized.

5), Details can be reproduced successfully with a high degree of precision.

6), Die Casting dies to retain their accuracy and usefulness for a long time, dies lifetime for zinc alloys is around 0.2 million, die casting mold lifetime for aluminum can meet up to 0.1 million short.

7), For mass production die casting is very economical due to the elimination of machining and mold making resulting in the saving of labor and time.

8), Because of the uniformity in wall thickness less material is required in die casting than in sand casting and the CNC machining parts

The disadvantage of Die Castings

1), High cost of the equipment and dies used requires sufficiently large quantities to compete economically with other processes, For die casting minimum economic quantity is considered like 5000-20,000 pcs per production lot.

2), there is a rapid decrease in the life of the dies as the metal temperature increases.

3), In some cases, there is an undesirable chilling effect on the metal.

4), Metals having a high coefficient of contraction must be removed from the mold as soon as possible because of the inability of the mold to contract with the casting.

5), there is a certain limitation in the shape of die castings and the process is not adapted to the production of large castings, so far the maximum size cast is 10 Kg in zinc and 30 Kg in Aluminum.

6), Die castings usually contain some porosity due to the entrapping of air.

7), Die casting has, to a large extent, been limited to low melting nonferrous alloys.

8), the surface treatment like anodizing is still not a better option on aluminum die casting products

If you have any project that needs zinc, magnesium or aluminium die casting mold/tooling manufacturing company? You are welcome to contact us anytime.