Plastic mold is an essential manufacturing tool to obtain plastic parts for large volume production, it's widely used worldwide for various kind of products. Nearly every products need a plastic mold tooling for manufacturing. This is why a plastic mold is also called "the mother of industry". Needless to say, you can image how important a plastic mold is.

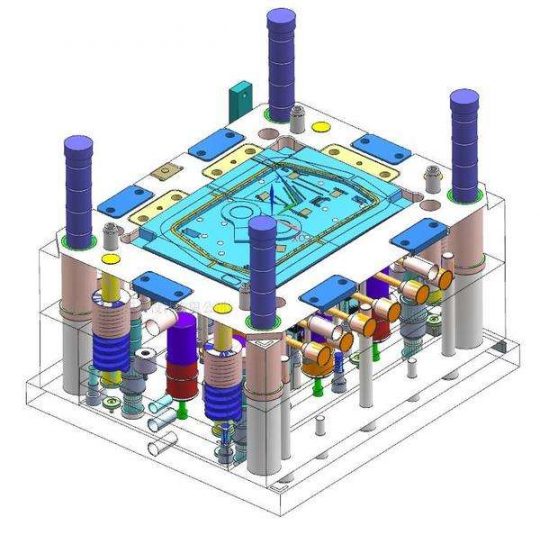

Plastic injection mold is normally made from steel, consists of cavity side, core side, injection system, cooling system, and ejection system.

When injection molding process, the injection molding machine injects melted plastic material onto mold tool through the runners and gates, it solidifies on the mold tooling to obtain the desired plastic products. finally the parts is ejected off from the mold tooling by ejection system.

For different process, a plastic mold can be divided into injection molding, blow molding, squeeze molding, and extrusion molding process. however our company mainly focus on custom plastic injection molding services.

Injection Mold – A steel(some of aluminum) made tool that used for injection molding to produce plastic parts in large volume.

Cavity – The interior chamber of a mold tooling that the molten plastic material is injected into and solidified to create desired plastic product.

Core – A protrusion feature inside the mold tooling, which work with cavity to obtain the shape of plastic product.

Mould Base – It’s a supporting plate that the mold core and mold cavity are attached inside. On the other hand, mould based is used to clamp the whole mold on the injection machine when injection molding process.

Parting line – A divided line on a plastic product, which used to weld the mold cavity and mold core together.

Draft – It’s an angle or degree on the plastic products, which used to easier depart the plastic product from mold tooling.

Sprue – A round chamber that transfer plastic material from the nozzle through runner system in the mould tooling.

Ejection pin – It’s metal shaft/pin that push off the plastic products from the mould.

Vent – A small space in the mold between mold core and mold cavity. It allow pressure air that gave by injection machine to escape aside of mold, instead of staying at plastic product, and prevent injection molding defects to happen

Gate – The channel to carry melted plastic material to flow into the mould tooling.

Slider– A movement mechanical structure in the mold tool, which is used to form some special part features that a cavity and core can't achieve it.

Lifter – A slanting block inside mold tool to obtain some extrusion or recessed part features that a cavity and core can't achieve it.

Mold design the one of the most important process to make high quality mold. An experienced mold designer will consider a reliable, cost-effective, durable mold design solution. This is why we hired most sophisticated mold designers who have over 15 years of mold design experience.

Mold design the one of the most important process to make high quality mold. An experienced mold designer will consider a reliable, cost-effective, durable mold design solution. This is why we hired most sophisticated mold designers who have over 15 years of mold design experience.

We utilize Pro/E, UG, Solidworks, Moldflow, Auto CAD for mould design as common, but our creative mold designer would provide clients most economical, high efficient, and quality-oriented design scheme. It’s essential that we will create 3D mould drawing, 2D drawing, and engineering mold part drawing for our manufacturing department to make mold. Meanwhile we will have formal ECN to record all the drawing status and modification changes. They are all filed and traceable in our documentation department.

For different custom requirement, the mold base is optional for EDM, Hasco, EMP, Futaba, and LKM. However, we use LKM(China best mold base supplier) for most of molds, since they are quick, professional, reliable, so that we can focus on mold core and other mold accessories manufacturing.

Once the mold design is finalized, we get our mold core and other mold parts manufactured by CNC machine, which is the most critical manufacturing process in the mold making. CNC machining can be divided into rough machining and precision machining. At the early stage of mold manufacturing, we will normally leave about 0.3mm~0.6mm extra material for precision CNC machining or EDM process.

Once the mold design is finalized, we get our mold core and other mold parts manufactured by CNC machine, which is the most critical manufacturing process in the mold making. CNC machining can be divided into rough machining and precision machining. At the early stage of mold manufacturing, we will normally leave about 0.3mm~0.6mm extra material for precision CNC machining or EDM process.

If needed, we will put the rough machined mold steel to be heat-treated for HRC48 °C~52 °C, so as to obtain desired hardness of mold steel. It takes about 12~24 hours.

EDM is the most common way to achieve a some complex mold features, like holes, groove, pillar,arc, etc. This process take long time, but accurate shapes as we needed. Meanwhile,wire cutting is also another important machining ways to get holes and linear features. It's widely used in mold making process. However milling and drilling machining are only used to get some mold parts accessories, like, ejection pin, sleeve, or stopper,etc.

For some standard mold accessories(like hot runner, ejection pins, hydraulic cylinder, screw, springs), we out-source them from LKM, Hasko, Yudo,EMP, HEB. but we get them inspected before using.

Mold polish can be notified to make the injection molding process easier, as well as surface treatment. like high polish and matt polish.

After mold machining and mold parts are ready, it's the time to get all of them assembled together. We can also call it mold fitting. The direct way to check a mold is by mold trail. You can easily see how your final product to be.

If any mold improvement needed, our engineering team will follow up and troubleshot those imperfections. and make the final quality products for customer review. Once the final sample is approved by clients, we will get the molds textured. Then sign off the job.

Inno Molding is a high quality plastic injection mold manufacturer since 1996 in Shenzhen China, Our mold factory was certificated with ISO 9001-2008 quality system, covers about a 3,000 square meters of mold making shop, grouped with a 120-employee of high-skilled mold makers, mold designers, quality team, and project managers.

Inno Molding is a high quality plastic injection mold manufacturer since 1996 in Shenzhen China, Our mold factory was certificated with ISO 9001-2008 quality system, covers about a 3,000 square meters of mold making shop, grouped with a 120-employee of high-skilled mold makers, mold designers, quality team, and project managers.

We have rich experience in working with Europe and US mold standards like HASCO,DME, HEB, STRACK, OPITZ, etc. Up to now, our monthly mold capability is 40 sets mould(middle complex mold)

Here below is the industrials we served:

Automotive

Medical & Beauty Equipment

Home Appliance

Consumer Electronics

Industrial Products

Mold Manufacturing Standard: DME,HASCO, MEUSBURGER,JIS, ANSI, DIN, BS, LKM(China)

Mould Use-life: 500,000-1,500,000 shots

Mold Parts Tolerance: +/-0.005mm

Mould Base Supplier:DME,Hasco,Futaba, EMP, LKM(China)

|

|

|

|

|

|

Mould Steel:

LKM(China): LKM2311, LKM2312, LKM2344, LKM638H,LKM838H, LKM2711, LKM718H, LKM738H

DAIDO (Japan): NAK55, NAK80. DC11, DC53

DIN(Germany): 1.2083, 1.2316

AUBERT & DUVAL (France): ADC3, SMV3W

ASSAB (Sweden): S136, S136H, IMPAX718H, STAVAX

FINKL (America): P20HH, P20LQ, H13

Hot Runner:Hasco,DME, Incoe,Yudo, Mould Master

Texture Standard:VDI 3400, Yick Sang, Tanazawa, SPI ...

Plastic Parts Application: PC, ABS, PMMA, PP, POM, PP, PE, PBT, PA, PSU, TPU, TPE, TPR, PVC, ect

When we take over a project from our clients, our engineering team will perform a detail DFM to analyze the part structure, material, assembly process. and provide our professional comments to amend manufacturability. Most of time, we will suggest customer to add fillets, draft, add or reduce wall thickness. Since this small action will prevent flash, shrinkage, unfulfilled, injection mark, etc.In this way, we can help clients to eliminate most of common injection defects, and keep the project risk under a controllable way.

Before initiation of a mold making, we will send our DFM report and mold design 3D drawing to clients to review and approve. In this way, our client will clearly understand how their mold would be designed and manufactured. If any imperfection or potential risk found, we can quickly review and work out a correction solution

Our mold designers had worked some in big mold manufacturers before for many year. We can proud to say, 98% of our design can successfully manufactured and injection molded as expected.

Here below are our main design checklist:

Mold layout to show number of cavity, and how parts are located in a mold

Gate system including gate type, position, size, and runner

Parting line simulation( it will tell show the parting line will look like for real injection molded parts)

Ejection system including ejection pin type, size, and position

Mold Flow analysis including material filling simulation, shrinkage simulation, deformation estimation, crack and other mechanical properties simulation

Material of core and cavity; mold base brand

Texture Code

Plastic parts material, color, finish, and weight

Injection molding machine choosing(tonnage and type) and parameter setup

Injection molding defects foreseeing and troubleshooting

It takes long time to manufacture a high quality mold, many clients don’t know how their mold project is going and which stage it’s moving forward. At Inno molding, we keep each project status updated to clients weekly. If any important matter or large project, we keep a weekly conference with client to discuss details instantly and interactively.

It takes long time to manufacture a high quality mold, many clients don’t know how their mold project is going and which stage it’s moving forward. At Inno molding, we keep each project status updated to clients weekly. If any important matter or large project, we keep a weekly conference with client to discuss details instantly and interactively.

Our update and conference agenda mainly contain:

Mold steel and mold base sourcing status

CNC rough machining process

Locating hole drilling and heat treatment

CNC precision machining

Wire-cutting, EDM, Drilling

Mold fitting

Mold trial

Defects found and improvement

Mold texture and last mold trial

Once mold making and trial have been finished, our in-site QC would perform strict mold quality inspection, and make sure our mold product would meet and exceed customers’ expectation. Especially for some exporting molds to oversea, we have to check them with our mold checklist one by one as below:

Once mold making and trial have been finished, our in-site QC would perform strict mold quality inspection, and make sure our mold product would meet and exceed customers’ expectation. Especially for some exporting molds to oversea, we have to check them with our mold checklist one by one as below:

All of sliders or lifters can move properly

Mold cavity and core move smoothly without interference

No burrs or sharp corners on the mold base

All of cooling outlets are equipped with proper adapters

Mold core, cavity, and mold base are sprayed with rusty-protection oil

Mold information brand is firmly fastened

Our parts inspection contains:

Part material is in accordance with customer’s definiation

Part color is correctly made according to pantone number

All of part features are correctly and completely made

No flash, deformation, shrinkage, crack, or other obvious appearance defects

All of critical dimension and control number must be measured and qualified by SPC process.

Part assembly test with other components from the whole system

Drop test, vibration test, salt-spray, rubbing test if needed