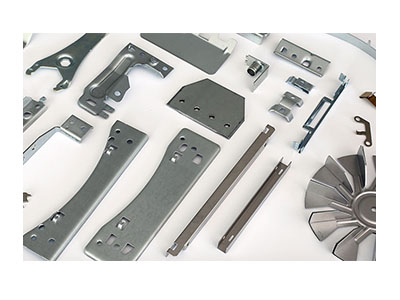

Features of stamped components:

·Product name: Sheet Metal Stamping Housing

·Material: Carbon Steel, Brass, Copper, Stainless Steel, Alumnum, Titanium Alloy

·Machining Tolerances:0.1mm

·Machining Process: Punching, edging, pressing and welding

·Min. Order:1000PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

As stainless steel stamping manufacturers, we provide excellent stamped components.

|

|

|

Description of stamped metal products

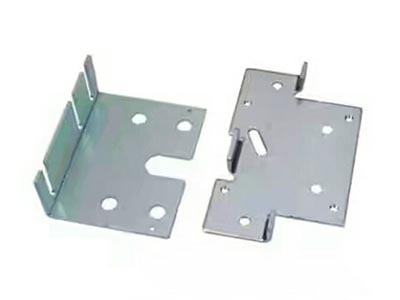

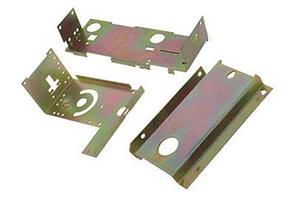

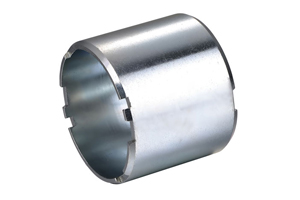

Sheet metal stamping housings are claddings or claddings made of thin sheets such as aluminum, stainless steel or brass with a variety of applications. The machining process takes place after drawing on CNC-controlled machines in several steps. In most cases, sheet metal enclosures protect the contents from soiling, such as moisture and dust, or protect the environment against shock, noise, or radiation. Typical application examples are chassis for electronic devices, control cabinets, medical products or display cases.

A core competence of our affiliated manufacturing companies is the production of customized sheet metal stamping housings in a wide variety of shapes and sizes. Due to the extensive range of services, there are no limits to the requirements of customers. Thus, waterproof, EMC-protected or prefabricated sheet-metal housings are produced according to your technical requirements as a prototype or series part on time from thin sheets of all kinds. Also, detailed work such as the attachment of threaded bolts or special surfaces no problem.

Design, material and production possibilities are important manufacturing factors, which is why a production planning is an important guarantor for customized sheet metal stamping housings. The production takes place in several steps with automated machines and plants. After precise laser cutting and accurate bending work , the sheet metal housings are given their individual shape with subsequent joining work such as welding , riveting or soldering. The conclusion is individual detailing and the application of the required surface coating.