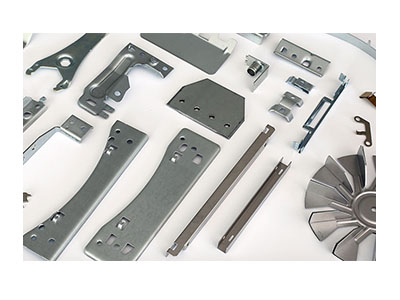

Features of metal welding parts:

·Product name: Metal Stamping Welding Parts

·Material: Carbon Steel, Brass, Copper, Stainless Steel, Alumnum, Titanium Alloy

·Machining Tolerances:0.1mm

·Machining Process: Punching, edging, pressing and welding

·Min. Order:1000PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

The stamped steel parts are of good quality and low price in our company.

|

|

|

Description of metal welding parts

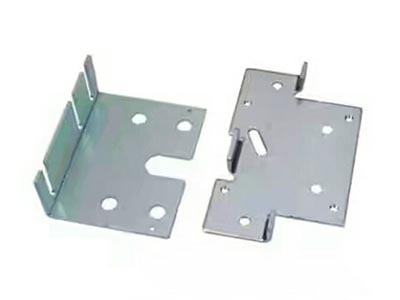

Metal Stamping Welded Parts are products made of thin sheet metal and are usually manufactured as assemblies or constructions according to customer requirements. The construction materials used here are sheets such as aluminum, steel, stainless steel or copper, which are joined together with suitable welding methods without burning through. Of course, all welded parts are subject to a comprehensive quality control and can be delivered with a wide variety of surface coatings. Typical applications are containers and apparatus for medical technology, enclosures for machines or systems for ventilation technology.

If you want absolute precision and a cost-optimized production of your bent sheet metal parts you are in the right place. Whether cantilevers or rounded sheet metal parts. In addition to simple sheet metal bending, Ningbo Hewcho also specialize in complex three-dimensional geometries. The production takes place according to need with hydraulic press brakes or most modern round bending machines. Since bent sheet metal parts often also serve as components for assemblies, we are also happy to advise you in questions of joining technology.

The production of bent sheet metal parts is done by bending. The most frequently used methods are folding, swivel bending and round bending. When folding , the sheet is pressed on a hydraulic press by a punch in the die and thus in the desired shape. When swivel bending the sheet is firmly clamped between the upper and lower cheek and is bent by the bending cheek to the bending rail. By contrast, round bending machines are equipped with several rollers, which gently round the sheet metal .

Information about other metal stamping parts

●Precision Metal Stamping Parts

●Auto Stamping Parts

●Stamped Aluminum Parts

●Custom Metal Stamping

●Sheet Metal Stamping Process

●Metal Stamping Housing